Mikeopsycho

Senior Chief Petty Officer

- Joined

- Feb 6, 2014

- Messages

- 738

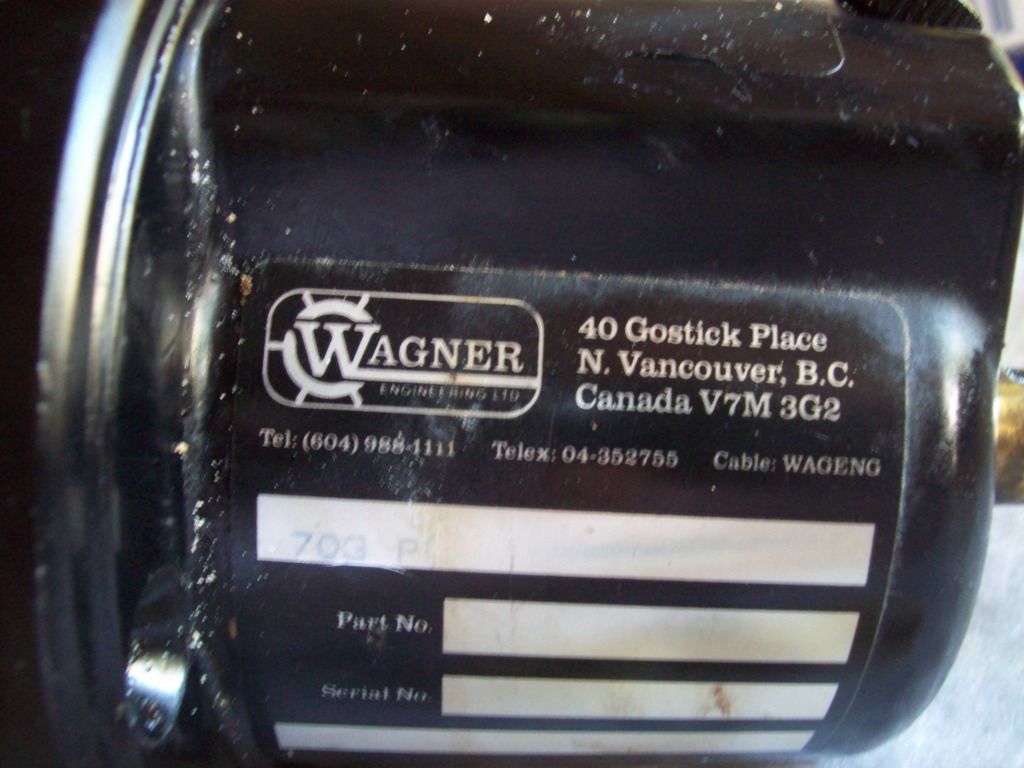

Better to find the crack now than peanuts laterIt looks to be modular and with a brand name so it looks like you have a fighting chance.

http://www.***************/buy/jabsco...11_334_002_004

looks like iboats is clipping out a competitor website from my url. Kind of like censorship. It rhymes with mestwarine.com

Hahaha. Let's see, questmarine, bestmarine, restmarine, jestmarine, wait, don't tell me, I'll get it.....

Hey KC, hmmm, EEEEpoxy might even do as a permanent repair :noidea:, I'll have to think about that :twitch:.

So yesterday I had to disconnect and remove the newly installed washroom taps so I could install the medicine cabinet :facepalm:, then put in the cabinet and remount and reconnect the taps. I'm hindsight it seems pretty obvious I was getting ahead of myself, I should have known the taps would be in the way, but I never even gave it a thought at the time. :stupid:

I roughed in a set of 14# wires from the machinery space to the V-berth through the cavity between the hull and the salon wall on the port side for a power point, then installed the cubby hole boxes. I also got the spice rack and table wall bracket in,

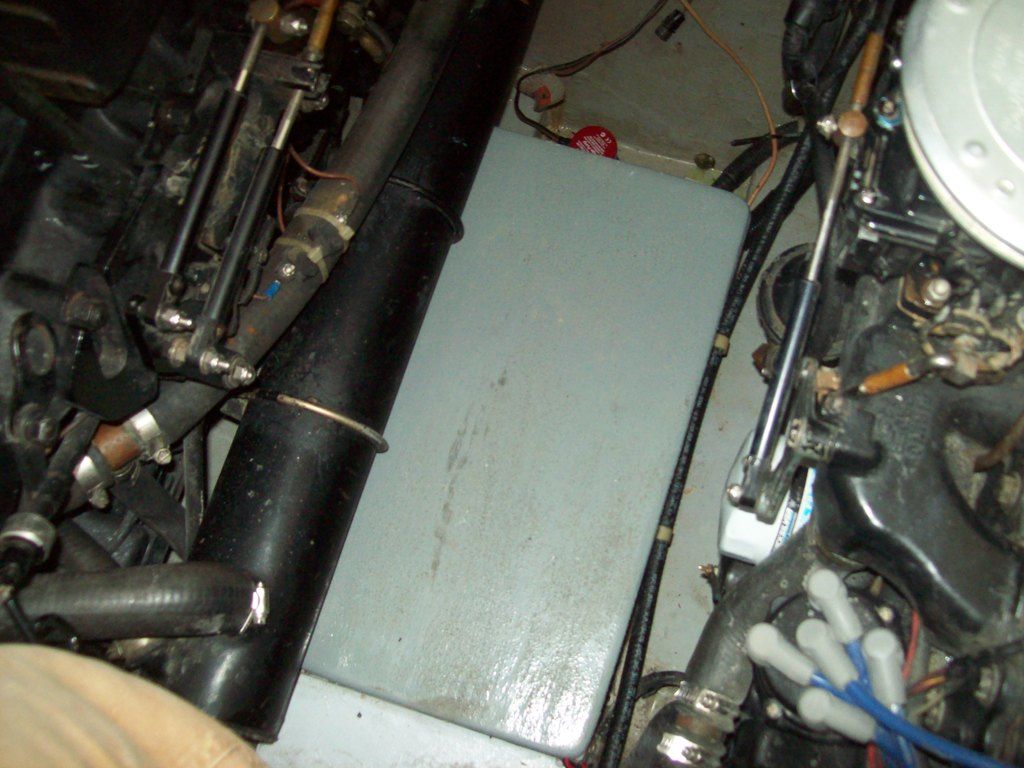

Then I got all the hoses installed through the firewall/bulkhead between the engine space and the salon. That's two hoses for the buss heater, hot and cold water hoses for the washroom vanity, and raw water hose and black water line for the head. Nothing like being jammed into a confined space with no room to move, your arms above your head, grunting and straining to push a spaghetti like hose through a too small hole, a hot trouble light cooking your side, and getting a cramp in your hamstring. I think I need yoga lessons. :wacko: I installed the trash can bin and the water heater platform, now that I don't need the space to stretch out in,