Craptin Mypants

Cadet

- Joined

- Jan 29, 2014

- Messages

- 15

I purchased my Carolina Skiff J16 a little over a year ago. I'm in it for around $600 after selling the 25hp motor it came with and using a 30hp I got for next to nothing. After using it for a year I am ready to make some changes to the layout. This is my first go at 'boat crafting/modificating'  , but considering what I have in it I'm comfortable climbing to learning curve with it. Here are some before pictures:

, but considering what I have in it I'm comfortable climbing to learning curve with it. Here are some before pictures:

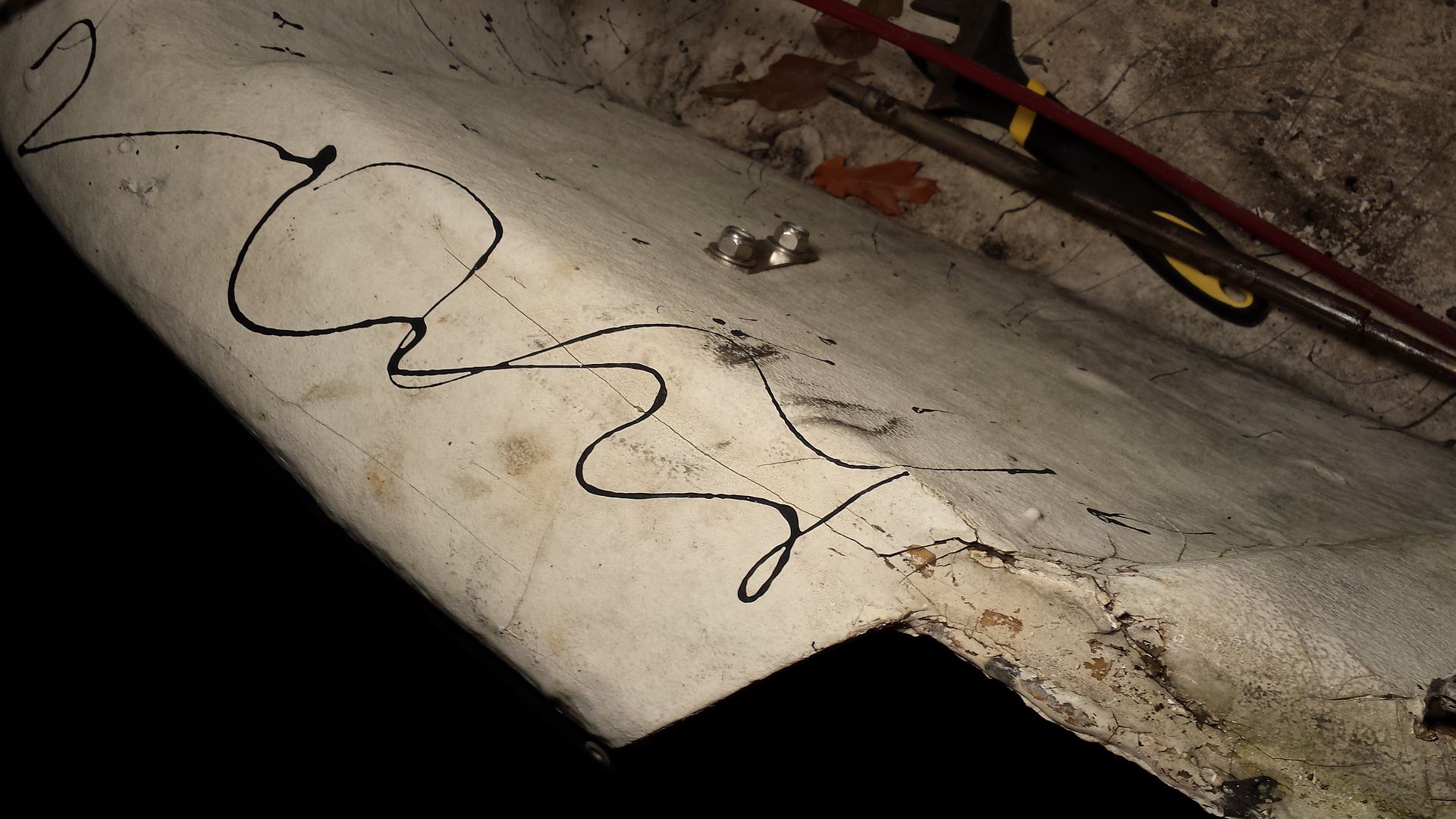

The day I got it

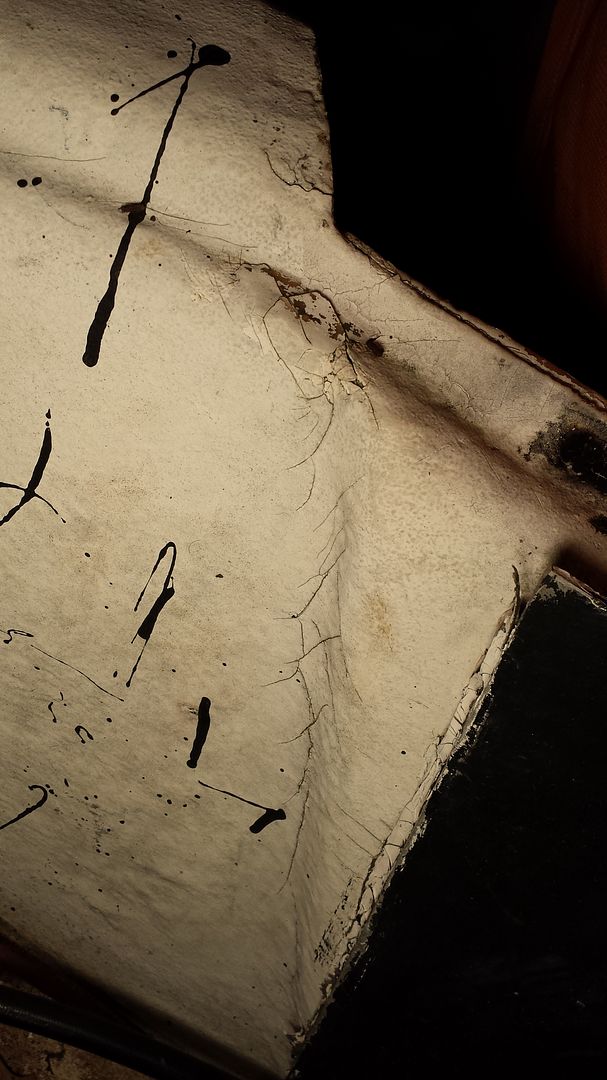

Before I started tearing into her

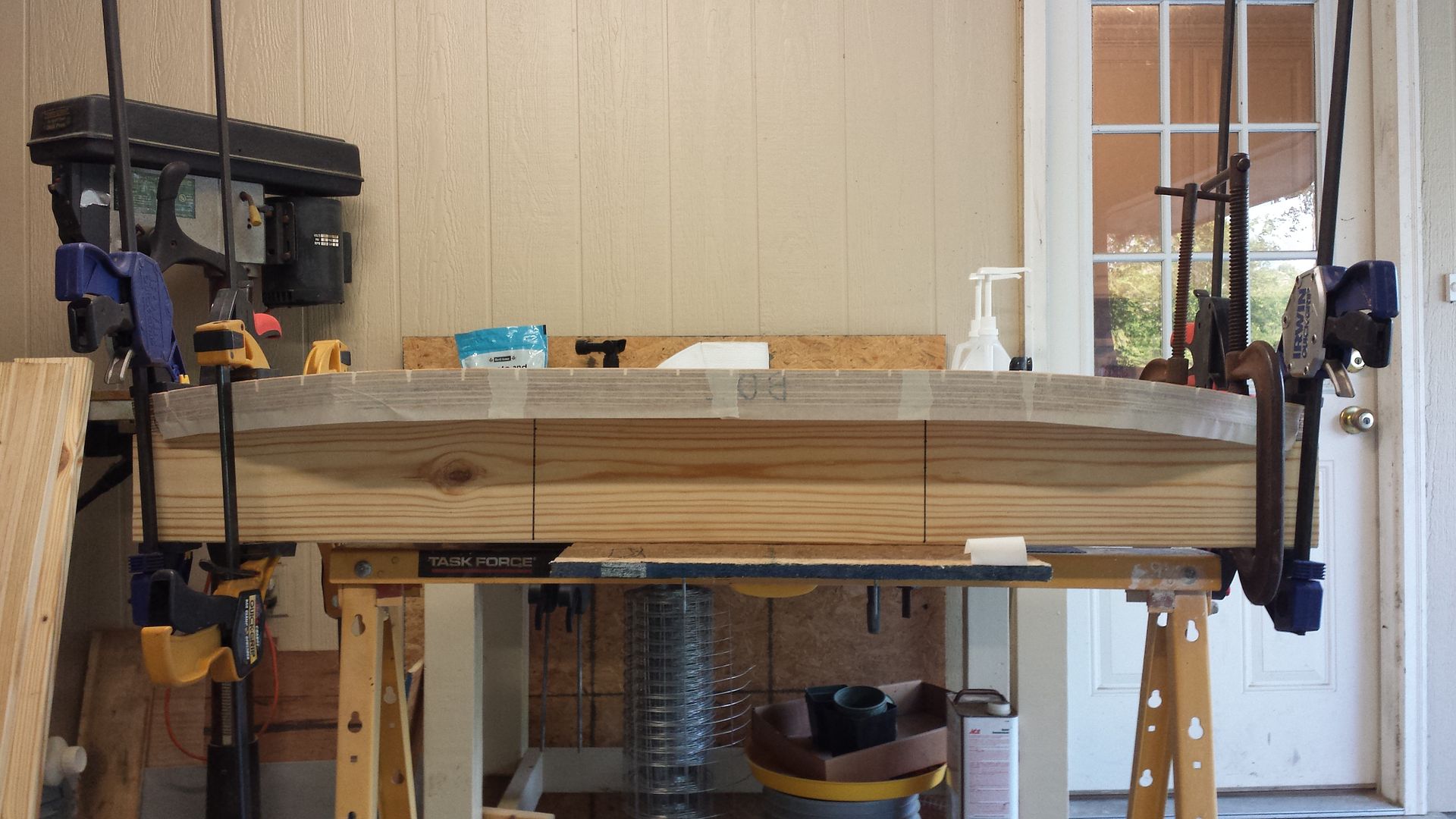

So, here is what I would like to do. I am going to take off the front deck and rear bench seat. I want put a larger deck up front, as well as deck the back to make it easier to fish from. I am also going to add some hatches to both for storage, and this will allow me to move both my batteries to the front to help shift some of the weight from the rear. Then lay down a nice new all white paint job on the inside (the previous owner tried their hand at a webbing job and failed miserably). Lastly, run all new wiring.

I am going to try to chronicle the project here, and hopefully you guys can provide advice when needed (probably going to be often). Here goes nothing.

The day I got it

Before I started tearing into her

So, here is what I would like to do. I am going to take off the front deck and rear bench seat. I want put a larger deck up front, as well as deck the back to make it easier to fish from. I am also going to add some hatches to both for storage, and this will allow me to move both my batteries to the front to help shift some of the weight from the rear. Then lay down a nice new all white paint job on the inside (the previous owner tried their hand at a webbing job and failed miserably). Lastly, run all new wiring.

I am going to try to chronicle the project here, and hopefully you guys can provide advice when needed (probably going to be often). Here goes nothing.