Re: 1957 Duracraft Duraflite Custom

After:

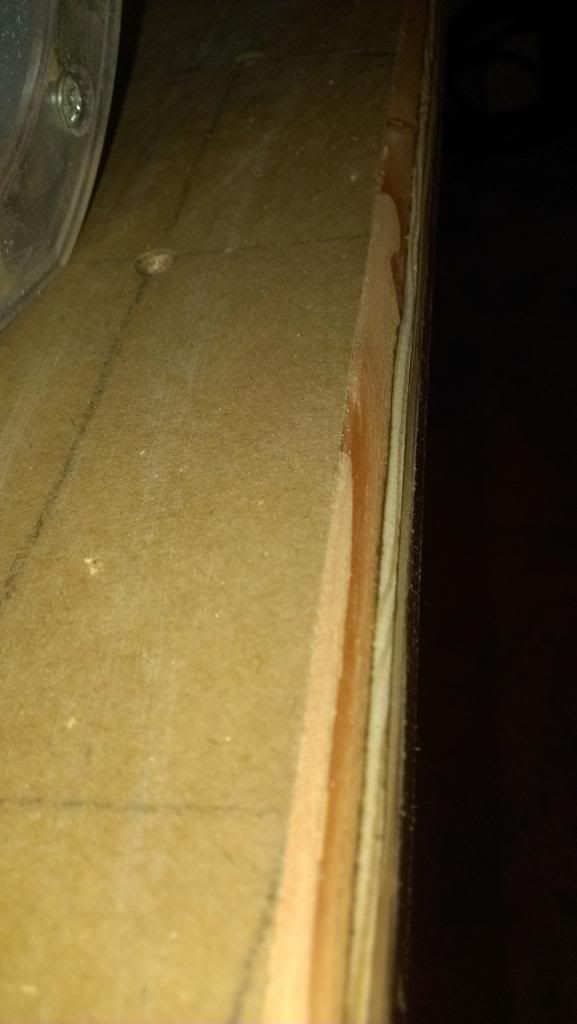

All drilled out ^^^

Until I can support the seat backs (which DON'T need to come out) I can't pull the front bench seat top.... So let's see what we can do about that...

I quickly bodged together a support system to keep the seat backs where they are currently:

And used a piece of 2X4 to keep the metal off the hull bottom:

It ain't pretty, but it'll do short term. I'll punch out the already drilled rivets and pull the seat top to access the foam & nastiness that likely matches the rear bench's heinous mess. Once all that is out, for now, I'll use some aluminum pop rivets (regular NOT closed or blind) to temp secure the top in place & pull my temp truss system. The weather is against me now, so probably not going to use the Gluvit/Coat-it on the seams & rivets for a bit.....

So, then back to work today.......

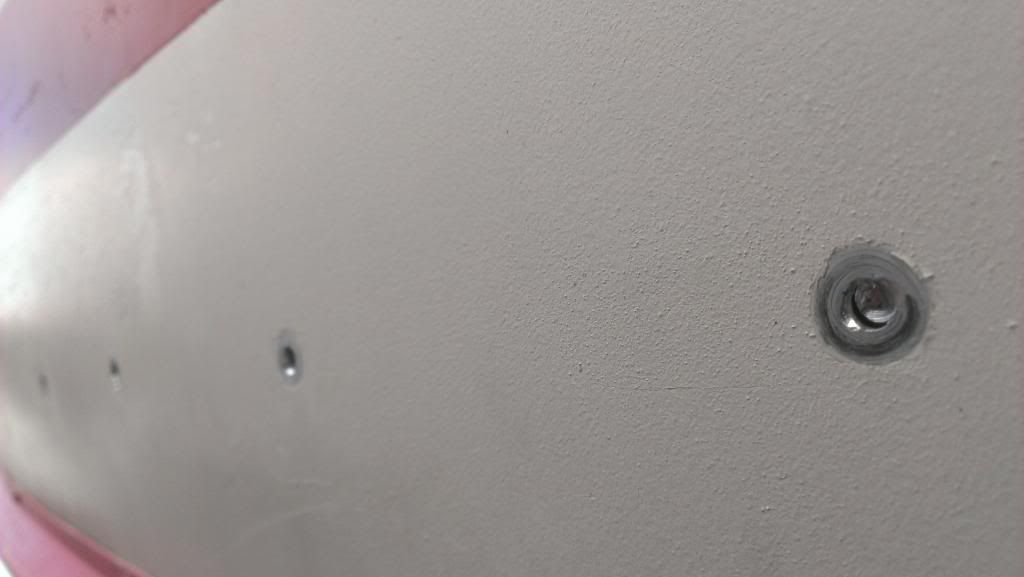

After I got the crew lined out & sent on their merry way, I broke out the resin & hardener and mixed up @ 12oz of Epoxy. And coated 1 side of the transom :triumphant:

Wow, until I posted that pix ^^^ I knew I'd made a mess, but didn't think it was that big a mess....

Jig, I have NO idea how you use that $5 plastic spreader for epoxy, but it didn't exactly go 'smoothly'......

Nor did clean up. Used acetone to try & clean the epoxy off the spreader, and made an even bigger mess.... Acetone dissolved the plastic...... So for the remainder of the show, I'll likely be using other means to apply epoxy......

Offending spreader:

Hey, we've made it thru the half way mark!

Have a great bottom half of the week!