Re: Conflicting stringer fiberglass layup diagrams

Ive thought about this for a while, after reading the West 550 sheet.

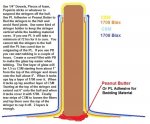

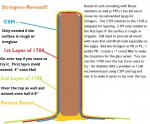

Based on the reading, it appears West is less concerned with adhesion, and concentrates on horizontal strength. Which makes some sense given that epoxy adheres better than poly. The guide repetedly addresses the importance of cap width, for horizontal integrety. Meaning that a 1/8 inch cloth cap requires a 6 inch stringer height, an 1/4 inch cap requires a 4 inch sringer, ect ect.

They also incorporate a full layover method, widest layer 1st. This kinda makes sense being that the layered strength would be in the upper lam layer of the build, if verticle strength was the intended result.

For a poly layup, the generally accepted method used here is right on, but for eopxy, it could go either way, imo

For me, given my situation increasing hp and torque, i decided to do the overlap tab in woods sig, minus the csm, then the West decreasing full overlay to current cap thickness, thus getting the best of both worlds...im using us comp epoxy and west fillers. .just one mans psychosis..