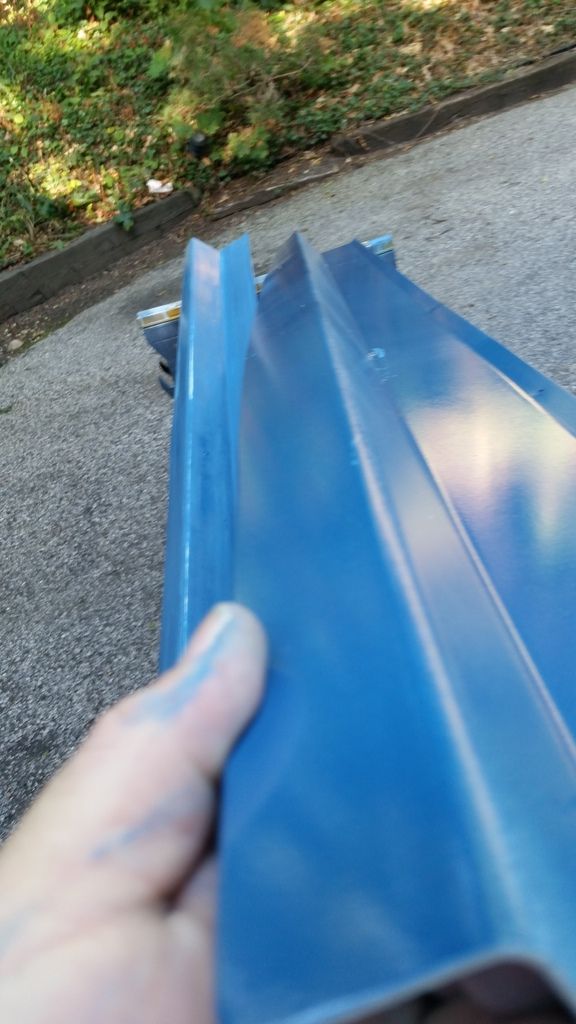

My boat is all welded. The stringers were welded in and left odd creases at weird angles all down the bottom of the boat.

They wouldn't look pretty polished. It is a shame because the blue would go great with an unpainted bottom. I will take the creases over bucking rivets and gluvit though and they really don't stand out with Paint on them.

The epoxy is actually loctite marine epoxy I used on my metal interior pieces to fill the pitting. I was going to buy jb weld but this stuff said it was good for aluminium. Anyway, I am going to etch prime the pieces and was wondering if I can etch over the epoxy.

They wouldn't look pretty polished. It is a shame because the blue would go great with an unpainted bottom. I will take the creases over bucking rivets and gluvit though and they really don't stand out with Paint on them.

The epoxy is actually loctite marine epoxy I used on my metal interior pieces to fill the pitting. I was going to buy jb weld but this stuff said it was good for aluminium. Anyway, I am going to etch prime the pieces and was wondering if I can etch over the epoxy.

Last edited: