Okay while the weather is starting to warm up (finally) I figured I better get a few things built in preparation. So here are the pictures of my version of a heavy five gallon bucket pouring device for the 435 polyester resin I will be using (hopefully tomorrow too):

I started off with two pieces of plywood found the centers and drilled a 1/4" hole part of the way through..

And I cut two circles and another one out of the center of one of them

Then I checked to see how everything was going to fit...nice so far.

I dado cut the thickness of the plywood on the two longer 2 x 4's so the top would have more support.

I also cut half the distance into the plywood to give everything a real solid fit.

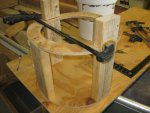

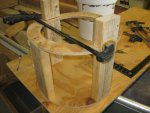

And with glue and screws, I assembled it this far.

Then I bought two 3/4" threaded pipe flanges and one 6" peace of thread 3/4" pipe. Both sides are now fitted with the pipe flanges

Next I cut that 6" 3/4" pipe exactly in the center yielding me two 3" sections and threaded them in.

Then I cut two sections of 2 x 4 and dadoed the center section of one 2 by 4 and rabbit cut the other piece of 2 by 4 so they will fit together very tightly for great support. Of course I made tow of these assemblies.

Then I drilled one 7/8" hole all the way through the top sections of the assemblies and glued and screwed the parts together. Very strong. I also drill two 1" holes in the lower sections but only 1" deep not all the way through.

Then on my wood lathe I turns two 1.5" by 1.5" square sections with a 1" dowel section on both ends, and I also turned a little bat looking part with a 1" dowel section as well.

Now you can see what those 1" dowel sections were for. Extremely strong joint. I don't think I could break a 1" dowel section off...

And a final picture of its last glue up. Amazingly solid!

And the final test to see if it was going to work. That is one of the five gallon buckets of 435 polyester resin in that contraption. You can tilt and pour with one finger. If you can see I drill some small hole for cotter pins in both ends to secure everything in place. Put honestly . I can see how anything would come apart. The top wood strap actually clamps down just a little to secure the bucket from moving and holds it totally solid and in place...

Well there it is. Solid, easy to use and a total back saver for me. I know it looks stupid, but it works and tilts like it is on ball bearings. :facepalm: