Something2do

Seaman

- Joined

- Oct 21, 2012

- Messages

- 55

Hello Everyone,

I have the eventual goal of restoring an older model Bass Boat: Skeeter Starfire, Basscat Panterra, etc sometime soon. While I was looking for the perfect candidate boat, I came across a smaller 14ft mostly fiberglass boat that I thought would make a great practice boat for my glassing, sanding skills and also test my resolve for a larger project.

I hope you feel that this small project is worthy of iboats. I am a huge iboats fan mostly because everyone shares their valuable knowledge and experience so generously with others.

Here is the boat: The style was some kind of combination rowboat, sailing dingy. (Do you like my workshop?)

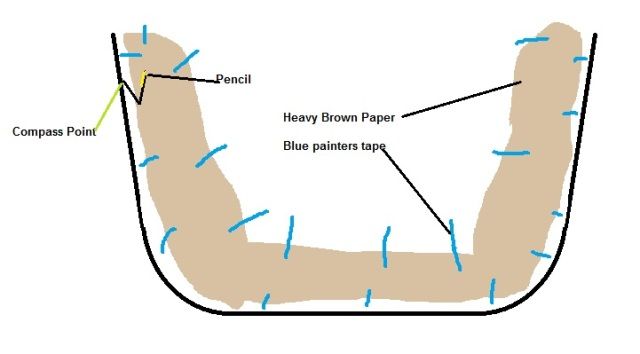

The boat is mostly made of fiberglass and it seems structurally sound for the most part. There are some glassed in foam supports running horizontally across the interior (what is the right term for these?) that are cracked and had to be removed.

I removed these and the foam with my grinder:

You can see in teh above picture that there is a big hole in the bottom of the boat. This was for a dagger board that was used in the orginal sailing configuration. I cut the dagger board extension off and grinded that flat with the foam supports.

There was a glassed in area in the rear of the boat that held some flotation foam. I was going to leave it alone, but when i cut the cap off the transom, it was all rot. To get the transom out, I had to cut out the rear area and remove all the foam. I did all of this work with the grinder as well.

I have the eventual goal of restoring an older model Bass Boat: Skeeter Starfire, Basscat Panterra, etc sometime soon. While I was looking for the perfect candidate boat, I came across a smaller 14ft mostly fiberglass boat that I thought would make a great practice boat for my glassing, sanding skills and also test my resolve for a larger project.

I hope you feel that this small project is worthy of iboats. I am a huge iboats fan mostly because everyone shares their valuable knowledge and experience so generously with others.

Here is the boat: The style was some kind of combination rowboat, sailing dingy. (Do you like my workshop?)

The boat is mostly made of fiberglass and it seems structurally sound for the most part. There are some glassed in foam supports running horizontally across the interior (what is the right term for these?) that are cracked and had to be removed.

I removed these and the foam with my grinder:

You can see in teh above picture that there is a big hole in the bottom of the boat. This was for a dagger board that was used in the orginal sailing configuration. I cut the dagger board extension off and grinded that flat with the foam supports.

There was a glassed in area in the rear of the boat that held some flotation foam. I was going to leave it alone, but when i cut the cap off the transom, it was all rot. To get the transom out, I had to cut out the rear area and remove all the foam. I did all of this work with the grinder as well.