Re: Bending plexiglass for curved windshield

I found this and thought you might be interested...

Make Your Own Curved Windshield for $100

I have a 1993 Mariah Diablo that had a broken windshield when I bought it. I could have had an original glass replacement for a mere $3885. A plastic's company could have provided one if I sent them the window frame and 8 weeks later and around $6-700.

I removed the left front window as they are the same size. I placed double sided tape on the windshield, applied construction paper and traced around the outside edge. I removed the construction paper and cut around the edges including the pencil line. I now had a template for my new window....figure 1.

Next I took small pieces of duct tape and placed them on the inside/outside edge of the left front window. I then took 1x8 boards and cut them to align with the curvature of the window. I numbered these 1, 2, 3, & 4. You also have to measure how far apart each board is from the one next to it. Beings you are constructing the opposite sided window...when you go to construct this form, the one on the top is now the one on the bottom as you will be flipping this form over. This took me about 3 hours to measure.....trim...and construct. It helps to have spare pices of lumber and an air nailer. Figure 2.

I then placed my paper template on the form and traced around the outside edge, so I'd know where the edges should line up when they are heated. Figure 3.

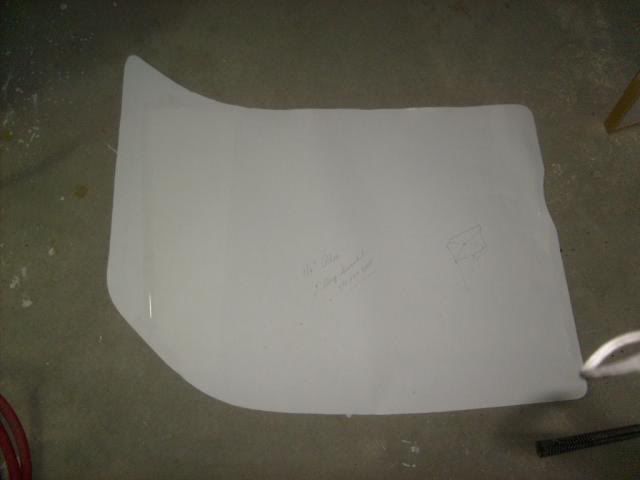

I contacted a glass company and they cut out my template using marine grade plexiglas (1/4 inch thick) for $60. I then used spring clamps and attached the glass to the flat edge of the form. I'd bought a heat gun and started heating away. Do NOT buy the cheapest Heat Gun. After 2-3 hours, I'd returned mine and bought a better gun (Wagner) for $40 dollars. This time I placed the glass in my mold at the curved edge. I'd clamped it with a 1x2 and started to heat away. You have to heat with the curve, going top to bottom.

Plexiglas melts at 250 degrees. My heat gun has a digital readout and I had it way above that. Go back and forth about an inch from the glass. If you nick the glass with the gun it will leave a scar, it will buff out later. The weight of the other end is all it takes for the glass to lay down as it heats up. Don't bother trying to clamp it, if it is not bent all the way..clamping will not bend it further. You may want to clamp it when you are done so it keeps its shape as it cools. You may hear a slight cracking sound as it heats and that is normal. It takes patience and 3 hours to complete this step.

If I had to do it again....I would have gotten some aluminum sheeting used for ductwork and made a mold using that. Put it in the frame and solder the mold in place. The window did need a minor adjustment with the very back upward corner. It is in the boat. Last figure.

The glass was $60, heatgun $40, 1 x 8 lumber $10. Probably 12 hours labor. Saving thousands or hundreds of dollars.....worth it. If you have questions, hit me up.