4Winns2

Petty Officer 1st Class

- Joined

- Nov 2, 2006

- Messages

- 327

Re: 1976 Century Arabian - Mercruiser 888 - Boat Restoration

4Winns, I appreciate the comments on the work. Believe me, it is nothing to be intimidated by, especially when you consider the date I started. One little step at a time (the one year hiatus didn't help). I think about the process during the week and try to be as efficient as possible in the few hours available on the weekend. Thanks for the link also. I have not yet seen this and I love the history. Purchasing the Century book is probably in the near future.... thanks guys.[/QUOTE]

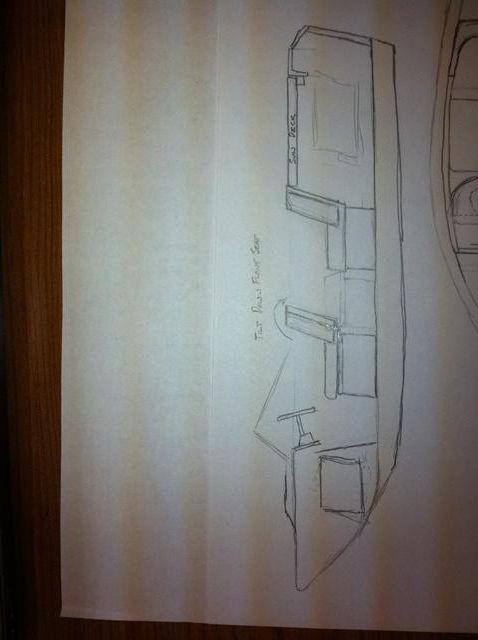

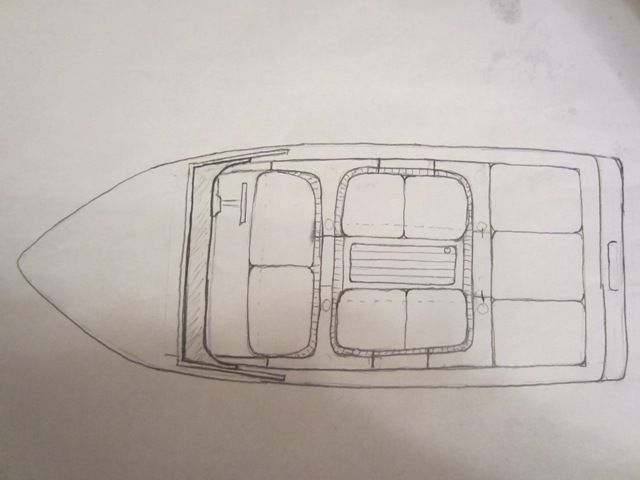

I agree, be efficient by setting manageable goals given the time you have. I have pulled the interior and the carpet (link to my resto thread in my sig) and the next step is pull the gas out of the tank and the tank then cut out the deck. My camera will be busy for reference shots and all here.

FYI: you're the second Arabian resto on this forum. A year or two older and it's an inboard. If you haven't seen it here it is:

http://forums.iboats.com/boat-resto...arabian-total-restore-618011.html#post4308616

4Winns, I appreciate the comments on the work. Believe me, it is nothing to be intimidated by, especially when you consider the date I started. One little step at a time (the one year hiatus didn't help). I think about the process during the week and try to be as efficient as possible in the few hours available on the weekend. Thanks for the link also. I have not yet seen this and I love the history. Purchasing the Century book is probably in the near future.... thanks guys.[/QUOTE]

I agree, be efficient by setting manageable goals given the time you have. I have pulled the interior and the carpet (link to my resto thread in my sig) and the next step is pull the gas out of the tank and the tank then cut out the deck. My camera will be busy for reference shots and all here.

FYI: you're the second Arabian resto on this forum. A year or two older and it's an inboard. If you haven't seen it here it is:

http://forums.iboats.com/boat-resto...arabian-total-restore-618011.html#post4308616