Re: Back to work on sanding and grinding

Re: Back to work on sanding and grinding

Well a quick update with pictures to follow.

Flywheel, dampener and velvet drive is on engine and they are on the engine mounts and sitting in place.

Harmonic balancer, circulating water pump, pulley and exhaust manifolds are installed.

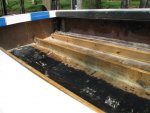

New shaft log is installed and the rudder stuffing box, shaft strut (With new cutlass bearings) and trim plate are all reinstalled and sealed up with 5200.

Picked up some of my hoses, my rebuilt prop (ouch!) thermostat, a new impeller and various bits of hardware.

Thunderstorms are predicted tonight and cooler weather tomorrow, so I'll have the kids before I can get much more done, but maybe I can at least put the raw water pump together and install it, the alternator and the thermostat and housing. Riser gaskets should be here by thursday so I should get the exhaust put together by Sunday.

Carb install and dropping the distributor are on hold til I get the engine lifted out and put back in one more time as I need to put my prop shaft in from the topside and it interferes. Once all that is together and aligned I can mark the stringers and pull the engine one last time, attach the mounts, lock tabs and lock washers and drop it in for the final time

(I'll probably lift that engine out a half dozen times more before I get it to my satisfaction)

Free beer offer still stands!

For the weekend fiascos

Repainted trim plate with Zinc Chromate and then Mercury Black. Flipped it over for the final coat and instead of hanging it just did it on some waxed cardboard-it stuck. Let it dry and sanded it out and repainted it.

Well we all screw up from time to time.

Went to install the transmission cooler-it is in primer-damn! cleaned and painted it. Looks good except I missed the underside of the fitting bosses. Time for more painting. Install is still waiting.

I'm not looking to bright am I?

Velvet drive mounts were installed upside down by the Borg Warner certified tech that went through it. On initial install engine pointed down instead of up at the bow. I should have taken pictures.

I am lucky I don't have to do this for a living.

hoist the engine and try again.

Neighbor built me new engine mounts. to give more bearing surface he made them out of deeper channel on the theory it would help spread the load-but He welded the plates the mounts bolt to to the bottom of the channel making them sit and inch and a half too low. I put it together without checking his works. I just might be a dumbass.

hoist the engine and try again

getting closer on this try, the transmission sat on the hull. Decided that left and right were not my strong suite in life. I am a dumb ***.

hoist the engine and try again

Reversed the mounts and dropped it back down. Getting closer. Shimmed the rear mounts. Looks like I have it! Realized I didn't install the oil drain hose and now I can't reach it. I can't put the prop shaft in without lifting the engine again.

I am a complete dumb ***.

Now you all know why I just bought a cherry picker instead of renting one.

Now for the dumb *** stunt of the weekend I tried to change the disc on my grinder to clean up the old engine mounts and managed to bump the trigger while my right hand was twisting the nut off with a pair of channel locks and my left was holding the grinder. Got away with just a couple of small scrapes.

I am a lucky dumb ***!

Got a lot done, but still a long ways to go. Hopefully I'll survive the restoration.