drewpster

Commander

- Joined

- Oct 17, 2006

- Messages

- 2,059

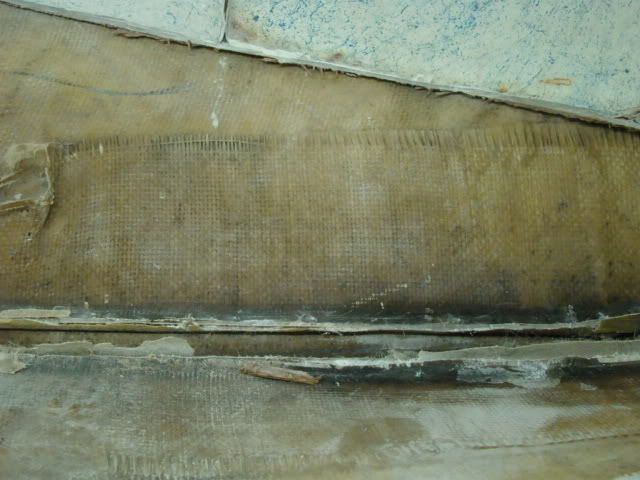

Ok folks I am joining the ranks of the unfortunate. The tri-hull needs a transom and here's how it goes so far. After getting over the shock and dismay of realizing the transom finally had to go I started by de-rigging. The engine was first to come off. She's old, but she's a runner.

Next I went about pulling the cables and wiring out. I removed the mounting screws of the engine controls and its cables came with it. There was corrosion everywhere in the wiring so it went to the heap.

I left the steering cable for last because it was the largest and most difficult to maneuver. I was going to leave the steering wheel and helm in place. But I was concerned about the weight of it pulling down on the dash boxes. I removed the helm and the windshield to shed a little more weight.

Next I went about pulling the cables and wiring out. I removed the mounting screws of the engine controls and its cables came with it. There was corrosion everywhere in the wiring so it went to the heap.

I left the steering cable for last because it was the largest and most difficult to maneuver. I was going to leave the steering wheel and helm in place. But I was concerned about the weight of it pulling down on the dash boxes. I removed the helm and the windshield to shed a little more weight.

Last edited: