QuickPuppy

Petty Officer 1st Class

- Joined

- Oct 18, 2017

- Messages

- 230

Hello all, bought my first boat last week having owned PWC's for the past 25 years. Found this 1999 Larson 186 SEI SF with a Johnson 115 OB on Craigslist. For the year and price, I thought it looked decent enough that I decided that whatever gotchas popped up would still be in my budget.

Took it home and scrubbed everything down and it really is cleaning up beautifully. Looks like the gel coat will shine again. The rough running engine the owner had mentioned in the ad actuallly sounded fine and I figured any issues with it were likely fuel related after sitting for the past year. Dumped a can of Seafoam in the tank and I'll pump it out and fresh fill before I try running it again. It will need a steering cable as well.

The PO had done some decent re-upholstery on most of the seat cushions. He had also laid a new carpeted wood floor over top of what he said were a "couple of soft spots around the captain's chairs". I planned to take that up and fix it right as it was surely continuing to rot now that it couldn't breathe anymore.

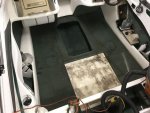

It was very wet under the floor in the ski locker and in the stern area (prior to me washing it) so I opened everything up and let it air out for a week. Today I decided to start taking up the deck overlay. Well, the "couple of soft spots" was the understatement of the year as about 80-90 % of the original deck was mush... From under the pass through all the way to the bilge. Even some of the foam had begun to hold water. My original thought was that I was going to be able to reuse the overlaided deck as the new floor but I'm going to be replacing more than that it appears.

One of the guys at Larson told me that the stringers on this boat were wood. So far, all I seem to be finding is foam and fiberglass. There are some wood braces over the fuel tank. Anyone know if there is wood under some of this fiber? Hoping no as it would be great if I didn't have to replace stringers too!

Any recommendations for where to get pressure treated plywood that fiberglass resin will stick too? I'm guessing the green "wet" stuff at HD isn't going to work well.

Trying to figure out how to get more pics to upload... more as I progress. Any tips are welcome!

Took it home and scrubbed everything down and it really is cleaning up beautifully. Looks like the gel coat will shine again. The rough running engine the owner had mentioned in the ad actuallly sounded fine and I figured any issues with it were likely fuel related after sitting for the past year. Dumped a can of Seafoam in the tank and I'll pump it out and fresh fill before I try running it again. It will need a steering cable as well.

The PO had done some decent re-upholstery on most of the seat cushions. He had also laid a new carpeted wood floor over top of what he said were a "couple of soft spots around the captain's chairs". I planned to take that up and fix it right as it was surely continuing to rot now that it couldn't breathe anymore.

It was very wet under the floor in the ski locker and in the stern area (prior to me washing it) so I opened everything up and let it air out for a week. Today I decided to start taking up the deck overlay. Well, the "couple of soft spots" was the understatement of the year as about 80-90 % of the original deck was mush... From under the pass through all the way to the bilge. Even some of the foam had begun to hold water. My original thought was that I was going to be able to reuse the overlaided deck as the new floor but I'm going to be replacing more than that it appears.

One of the guys at Larson told me that the stringers on this boat were wood. So far, all I seem to be finding is foam and fiberglass. There are some wood braces over the fuel tank. Anyone know if there is wood under some of this fiber? Hoping no as it would be great if I didn't have to replace stringers too!

Any recommendations for where to get pressure treated plywood that fiberglass resin will stick too? I'm guessing the green "wet" stuff at HD isn't going to work well.

Trying to figure out how to get more pics to upload... more as I progress. Any tips are welcome!