Well I went from owning a little tiny one person kayak(first boat). To owning what I thought was a steal of a deal on a family boat, water ready.

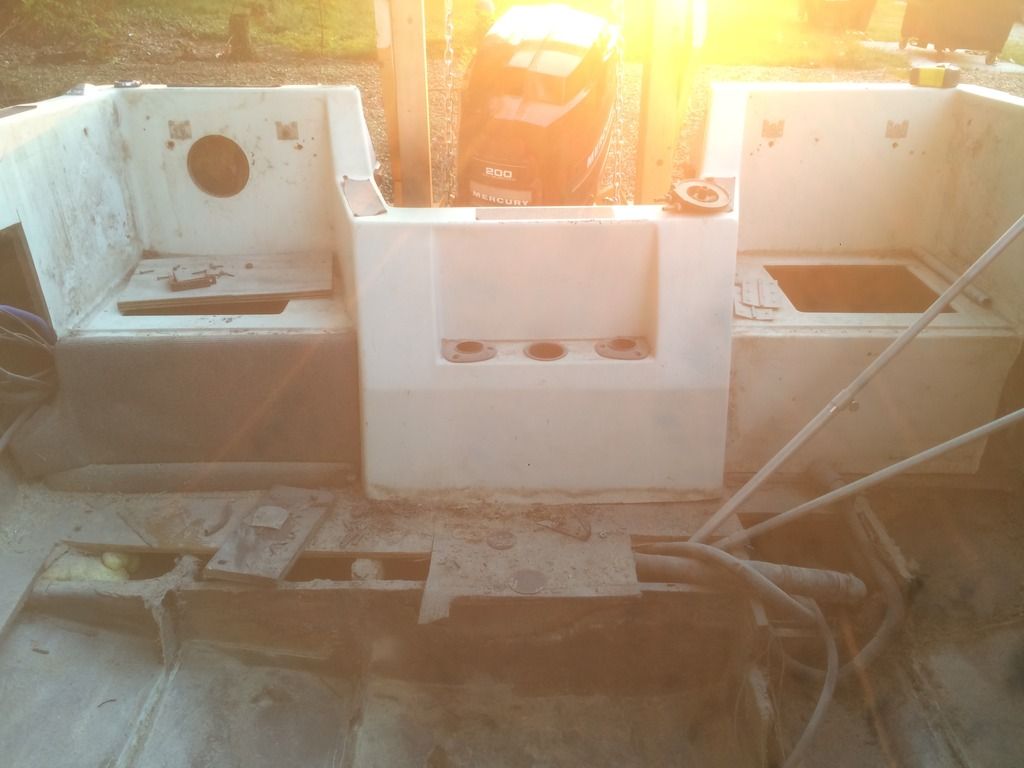

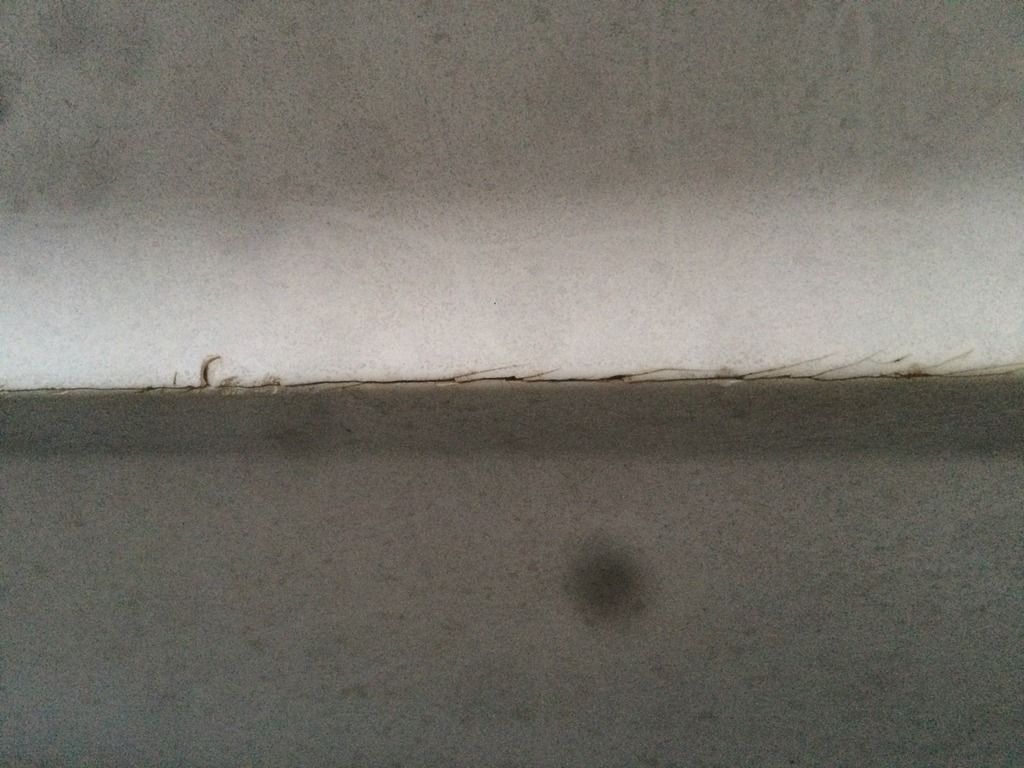

To now owning something that needs to be completely gutted and redone to be safe again on the water. I have already started the dismantling process. Mind you this is my first boat, learning as I go. Luckily I am confident in what skills I have to do this right, thanks to YouTube and this site.

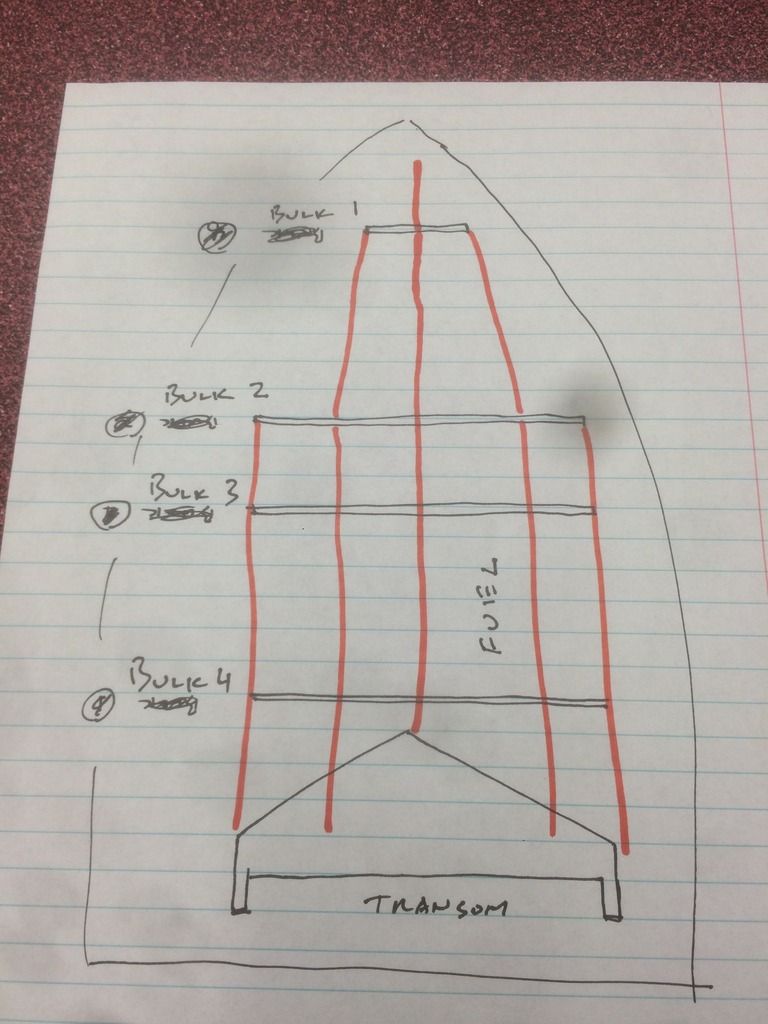

My question is how much material do I need? I've read a few other restore, and I saw 20gallon polyesters resin? Please help me determine how much material, so I don't order too much. Planning on redoing everything, stringer floor and possibly transom( haven't gotten in there yet). Thanks

To now owning something that needs to be completely gutted and redone to be safe again on the water. I have already started the dismantling process. Mind you this is my first boat, learning as I go. Luckily I am confident in what skills I have to do this right, thanks to YouTube and this site.

My question is how much material do I need? I've read a few other restore, and I saw 20gallon polyesters resin? Please help me determine how much material, so I don't order too much. Planning on redoing everything, stringer floor and possibly transom( haven't gotten in there yet). Thanks