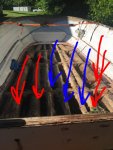

Lower, re-looking at your hull. it really looks like there was some type tubes installed instead of stringers on each side. And that may have been their answer to channeling water out of the hull if it got underneath the flooring. But that is only a wild guess with me.

I have no idea what you have plans to do. Maybe you have a plan all set out. If so let us know. I'd be interested in it.

However, If I were doing this, I would take all the existing stringers, and tube looking things out, and the grind the area for new stringer setup. Then I would install the new center section stringer, but not in the dead center. I would build the new stringer setup off the center on each side so water could flow easily in the center section. That is the lowest section of the hull and would be the collection point for water.

Then I would add two more stringers. One on each side a mid-point from the stringers you installed in the middle section to the side of the hull on each side. So it would actually be four total stringers. And that would be enough to support your flooring system without any issues. Sound like a lot of work, but when making stringers, you would simply produce two stringers of the exact same dimensions for each set, being how both sides would be equal. That probably sound a bit confusing so here is what I mean.

Then I would use some Mix and Pour 2lbs flotation foam and fill in all the out side areas with foam. Leaving the center section totally open for water to travel to the bilge area and be pumped out. But then again, this is just my opinion and other will have other ideas as well. JMHO