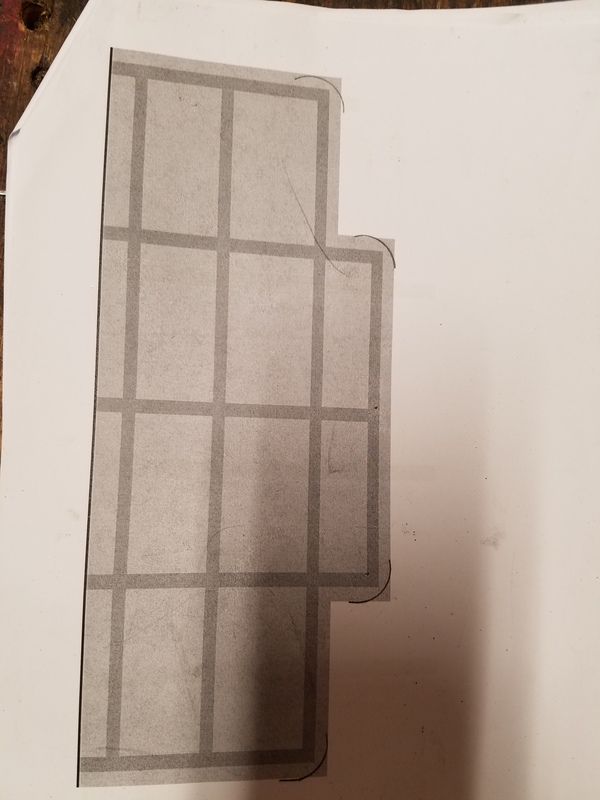

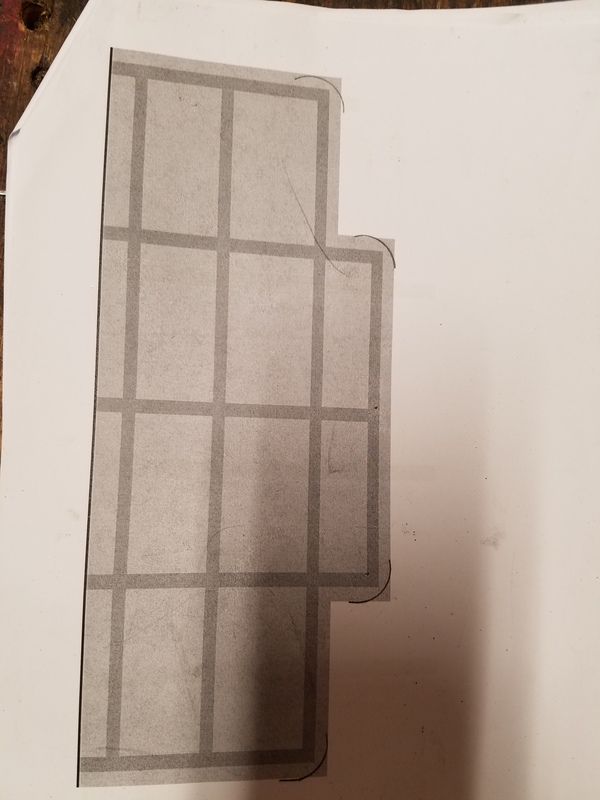

Here's a better look at my overall plan. 5 supports. The 3 middle ones go out 48" so that I can stand my inflatable row boat up on end, 70 lbs. No other weight will extend out that far. There will be a railing limiting travel to 36" out from the transom.

The 2 outside supports extend 36" out and due to the hull bottom, do not have enough room for a larger angle on the support.

The 2 outside supports extend 36" out and due to the hull bottom, do not have enough room for a larger angle on the support.