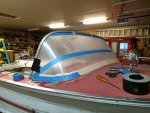

Wow, things are starting to happen kinda faster than I was prepared for. Just had to pay down for my soon to be new (to me ) used 40 hp merc, oil injected motor (1998 model). Planning for the spring rush, when the previous owner trades in (deals already done) I need to be ready to take my boat in for the transplant. There is so much that I think I need to do before all this happens, but what do I know, this is my first field trip. Then I get side tracked by a light/ flag pole brought to me by a buddy. A good companion for my original stern light to balance the boat. Done, now back to the list. Got the Transom totally installed including using the 5200 (still got that stuff stuck to my arms and hands). Decided to reinstall the steering wheel, etc, so I'll be ready when called. Now I can get back to sanding and priming everything. Seats and carpet came in, new distraction. Any thoughts on using Bilge area Paint for all of the exterior body sides. Its durable, glossy, and I already got it. I can't find any negatives that change my mind. The top will be red, thats not negotiable.