61mysteryboat

Petty Officer 2nd Class

- Joined

- Oct 22, 2015

- Messages

- 104

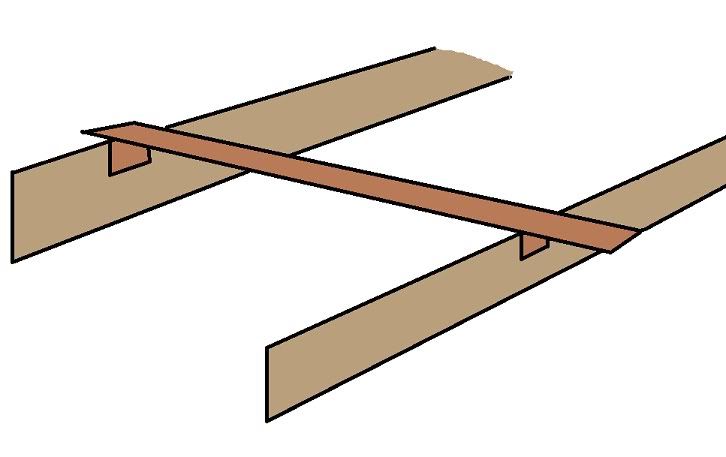

I am going to be replacing the wood stringers in a fiberglass boat. I have the old stringers removed and the bottom of the hull sanded down. I am going to have to lay an additional layer of fiberglass on to the bottom of the hull before I place the stringers. ( I ended up sanding into some of the old woven roving in order to get the old stringers out). My question is whether to use waxed or unwaxed resin when laying the fiberglass. I will be placing the stringers in a bedding Compound on top of that layer. If I use unwaxed resin will be bedding compound adhere to it. If I use the waxed resin I would end up sanding out a lot of that area in order to tab the stringers in place. I will be using loctite pl to set the stringers in and then filleting the wood to hull with pb. Any advice? Thanks.