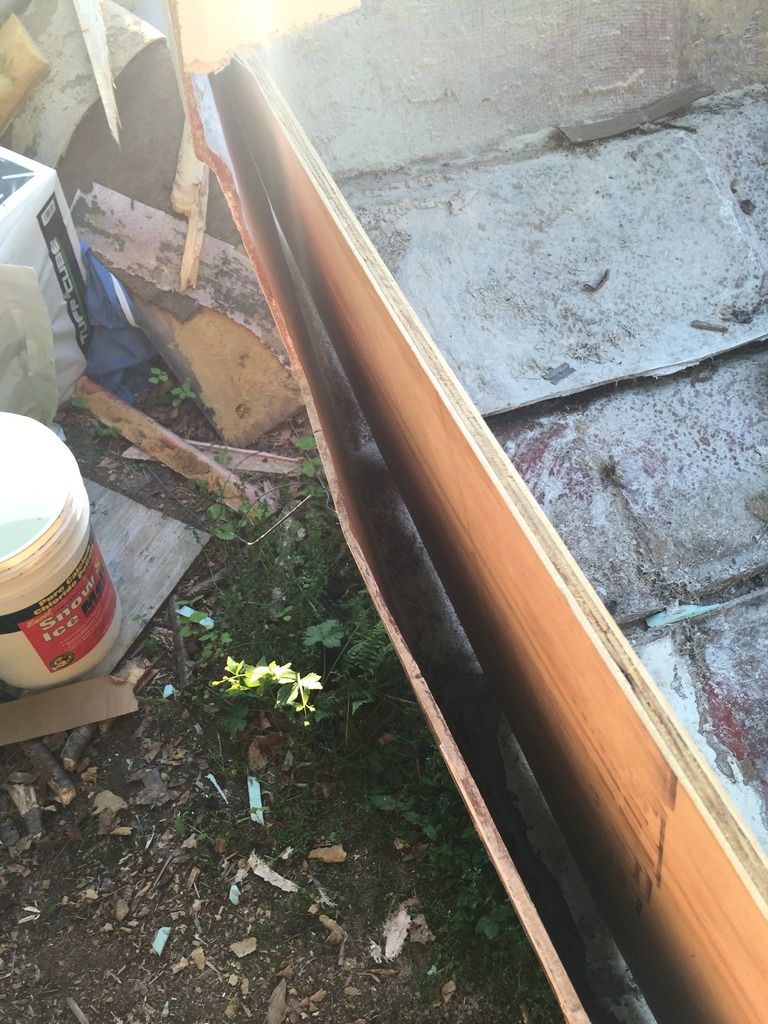

Hello all ! I'm brand new to this and determined to restore my boat of course. However, im stumped on the transom rebuild. I'm working with plywood and long story short, my transom has an angle in it. The wood Is extremely difficult to bend to the shape and I'm reaching out for the correct way it should be done. It was plywood before I tore it out due to massive rot. I'll upload pictures if t helps.

Thank you all so much.

Thank you all so much.