Acpics80

Seaman Apprentice

- Joined

- Mar 17, 2016

- Messages

- 41

Hello All,

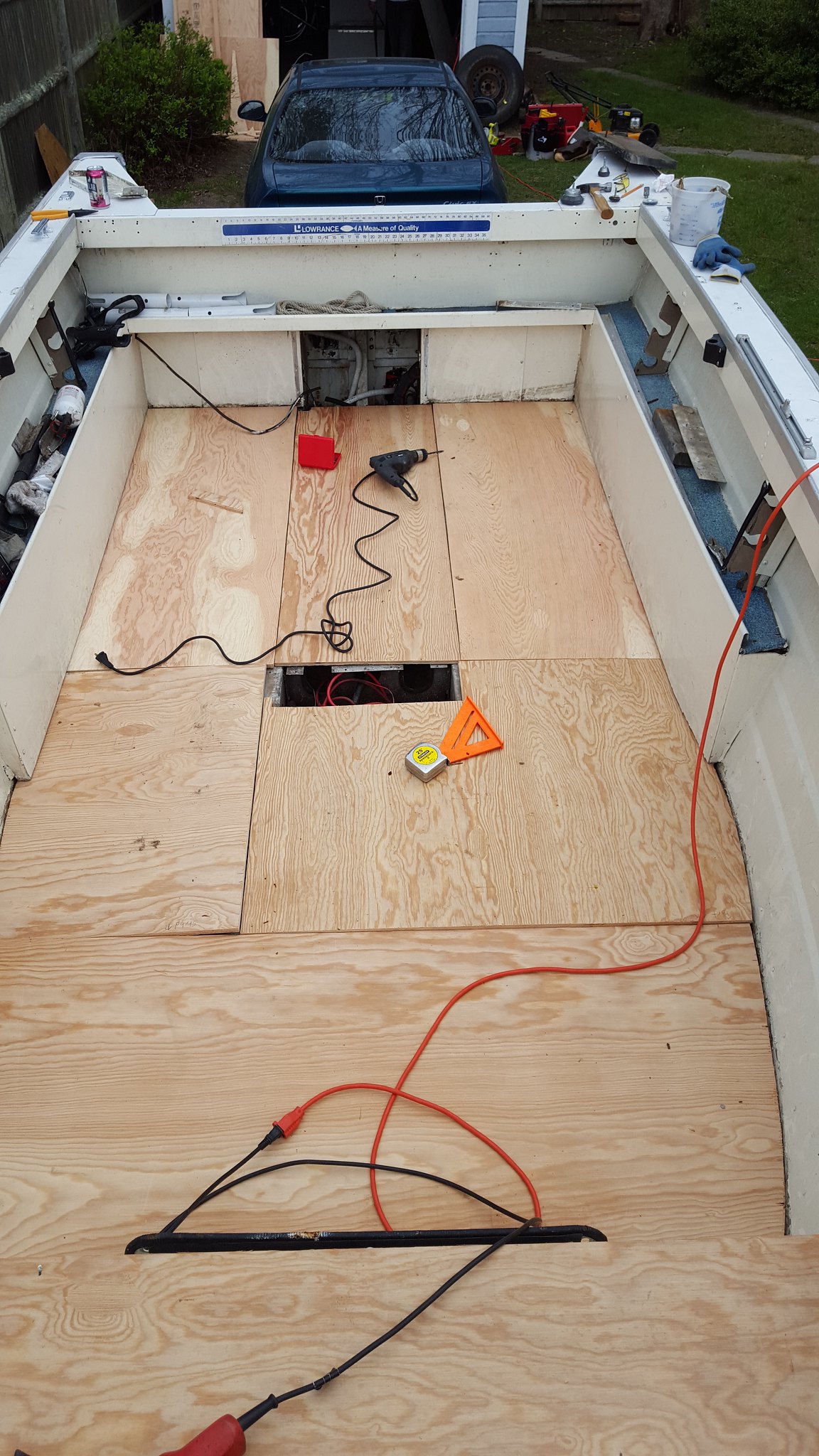

First I want to express how happy I am to have found the iboats community! I'm a member of several online fishing forums and while most provide some tips and help, they are generally only good for the occasional laugh and entertainment. The amount of knowledge and things that I have already learned from this group is staggering, and it is mostly to blame for the reason I decided to buy a project boat instead of a turn-key! So thanks in advance for all of your pictures, tutorials and tips, it has been a pleasure. That being said, I've decided a few months back to pull the trigger on a 1985 Sea Nymph CC-191. I've been searching for a long time now on an affordable boat, in a style that would fit my boating / fishing needs and when I saw this boat online I knew I had to have her! I currently live and do most of my boating on Cape Cod and although tin boats aren't hugely popular in my area I'm particularity fond of them and I'm excited to get her out on the water. Going into the purchase I knew there was going to be some work required but I contemplated for a short bit whether to start the work ASAP or use the boat for this season and tear into it during the off season. However, upon spending the first day with her inspecting from bow to stern, I decided to get right to work, even if it meant shortening my boating season this year. It has also been killing me that since I bought the boat, I've only had 2 weekends at home, the rest being spent 200 miles offshore on my "other" boat, a 208' fisheries research ship. So in my downtime offshore I've been devouring the iboats forums and trying to learn all that I can so that I can hit the ground running when I get back to shore. So that's a brief intro, as soon as I get another post I'll start adding pictures and I hope some of you will tag along during this rebuild to lend a hand, I can certainly use it!

Cheers!

Acpics80

First I want to express how happy I am to have found the iboats community! I'm a member of several online fishing forums and while most provide some tips and help, they are generally only good for the occasional laugh and entertainment. The amount of knowledge and things that I have already learned from this group is staggering, and it is mostly to blame for the reason I decided to buy a project boat instead of a turn-key! So thanks in advance for all of your pictures, tutorials and tips, it has been a pleasure. That being said, I've decided a few months back to pull the trigger on a 1985 Sea Nymph CC-191. I've been searching for a long time now on an affordable boat, in a style that would fit my boating / fishing needs and when I saw this boat online I knew I had to have her! I currently live and do most of my boating on Cape Cod and although tin boats aren't hugely popular in my area I'm particularity fond of them and I'm excited to get her out on the water. Going into the purchase I knew there was going to be some work required but I contemplated for a short bit whether to start the work ASAP or use the boat for this season and tear into it during the off season. However, upon spending the first day with her inspecting from bow to stern, I decided to get right to work, even if it meant shortening my boating season this year. It has also been killing me that since I bought the boat, I've only had 2 weekends at home, the rest being spent 200 miles offshore on my "other" boat, a 208' fisheries research ship. So in my downtime offshore I've been devouring the iboats forums and trying to learn all that I can so that I can hit the ground running when I get back to shore. So that's a brief intro, as soon as I get another post I'll start adding pictures and I hope some of you will tag along during this rebuild to lend a hand, I can certainly use it!

Cheers!

Acpics80