Hi all thanks for checking out my post. I'm considering fixing a 16' Rebel sailboat that took some serious damage along the deck-hull joint some time ago. I have some experience with fiberglass, but this would be the biggest project I've tackled. My questions are as follows:

1. Is this project a lost cause?

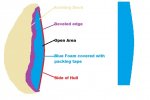

2. What is the best way to tackle the fiberglass? Should I approach the hull and deck components separately and then connect them? My thought is to divide and conquer: make a mold (likely out of some type of foam to run the length of the side) to mimic the curvature of the hull near the joint (see picture 1), and then make a fiberglass part with that mold. I would then do the same with the deck component, and after connecting both parts to the hull and deck respectively, I'd bondo or glass them together to fuse the joint. Then the whole boat would then get a fresh gel coat.

3. Picture 2 shows the extent to which the deck is cracked near the joint. Would I need to cut back the deck beyond the cracks to ensure a rigid structure or can I just cut along the side so as to get a clean edge? What do I sacrifice by cutting a corner here?

4. What type of fiberglass fabric should I use at which stages of the project?

My concern is that the fiberglass parts will not be strongly connected to either the deck or hull. Overall, it feels like there would be too much patchwork to ensure a solid structure -- although maybe this would be remedied by several layers of glass once the parts are fixed to the body but before they are connected.

Pictures 3 and 4 attempt to show the underside of the joint where the two components are joined together; the deck overlaps the hull by a few inches and they are bonded along the split line.

Again, thanks for checking in. Any input is much appreciated.

Evan

1. Is this project a lost cause?

2. What is the best way to tackle the fiberglass? Should I approach the hull and deck components separately and then connect them? My thought is to divide and conquer: make a mold (likely out of some type of foam to run the length of the side) to mimic the curvature of the hull near the joint (see picture 1), and then make a fiberglass part with that mold. I would then do the same with the deck component, and after connecting both parts to the hull and deck respectively, I'd bondo or glass them together to fuse the joint. Then the whole boat would then get a fresh gel coat.

3. Picture 2 shows the extent to which the deck is cracked near the joint. Would I need to cut back the deck beyond the cracks to ensure a rigid structure or can I just cut along the side so as to get a clean edge? What do I sacrifice by cutting a corner here?

4. What type of fiberglass fabric should I use at which stages of the project?

My concern is that the fiberglass parts will not be strongly connected to either the deck or hull. Overall, it feels like there would be too much patchwork to ensure a solid structure -- although maybe this would be remedied by several layers of glass once the parts are fixed to the body but before they are connected.

Pictures 3 and 4 attempt to show the underside of the joint where the two components are joined together; the deck overlaps the hull by a few inches and they are bonded along the split line.

Again, thanks for checking in. Any input is much appreciated.

Evan