My daughter's Sea Scout Ship in Baytown TX just received this 1978 Sea Ray SRV-260 as a donation boat. The previous owner had it 5-6 years and bought a lot of parts, rebuilt the shortblocks, rebuilt the outdrives, and more, but ended up buying a 34' boat that they keep at the marina and stopped working on this one. So his loss is my/our gain. I and the Skipper of our ship went and looked at it a few weeks ago and our initial thought was it was going to be too much work. It was going to need everything mechanical done and we weren't initially sure about the transom. It had 8" of water inside the cabin from rain and the motors/outdrives had been off it for quite a long time with an exposed transom/keyhole. The owner wanted to see her cleaned up and being used/enjoyed, so we initially declined that offer. Then he said he would keep the motors/drives if we just hauled off the boat/trailer. We thought that one over and figured the trailer should bring $1500 since it was in good shape. We started thinking about another vessel that was more/less offered to us that was similar in size, but did not have a trailer. We figure if we could go get the other boat and this one we could determine which was in the best shape and take parts from both to make one good boat, then scrap the other. Problem is that Skipper was in no hurry to do this and the more I thought about this Sea Ray and the more I looked up info on it, the more I started to like it and think it would make a good boat for me and my family. That said, I went ahead and picked it up last weekend regardless of what we as a ship decide to do with it.

I started cleaning her out this week, maybe 30 minutes to an hour a day to pump the water out and clean out the leaves/trash that has accumulated over the years. I've got it to a point where I can either use my blower or vacuum cleaner to get the rest of the leaves/debris out and got a good cleaned up area to work with and get a few pictures.

I've been reading iBoats off and on for a few years now. I started reading when I figured out that my 97 Chris Craft 170 ski boat was going to need a transom. I decided that job was too tough for me to tackle at the time and took the boat to a local fiberglass shop to get it done and he did a great job. The boat is solid and doesn't get a drop of water in it unless the kids get in soaking/dripping wet LOL. That said I know I need to drill a few core samples of the transom and stringers. From what I've found online the 1978 Sea Ray was the last year that Sea Ray used the extra thick fiberglass method to build the boat. So it is considered to be pretty heavy duty in terms of construction. I'm really hoping the stringers are OK and honestly hope the transom is OK too because that's a big transom and a lot of work on top of having to potentially rewire, replace the steering, replace the engine cover floor door, replace the throttle assembly, replace all carpeting/padding below, and who knows what else. At this point, I just want a good dependable boat that I can take a couple miles off shore and go scuba dive some rigs in the gulf. The cosmetics can be done later as time/money permits. I just need the drivetrain to be solid first.

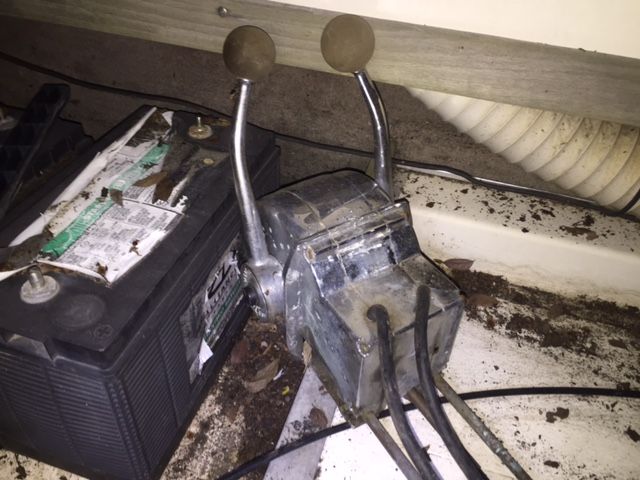

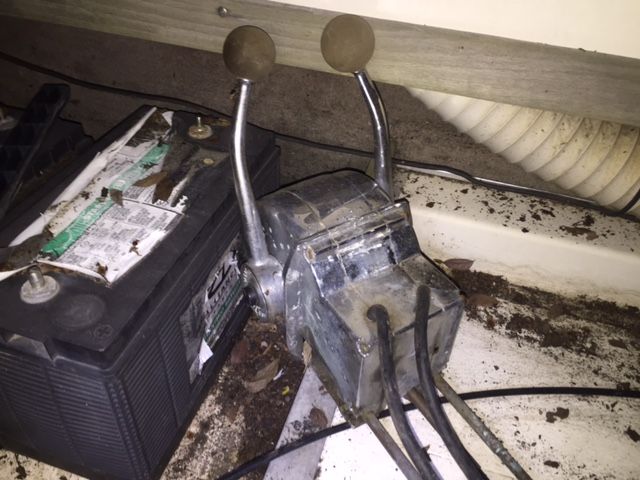

I haven't snapped any pics in the cabin area yet, but I'll get those and post them eventually. The few pics I have were mostly taken in the evening after I cleaned out a bunch of trash. I just wanted to get some shots of the engine bay and key holes up here so you guys could take a look and give me your thoughts.

The engines I'm told are straight 6 cylinders with Mercruiser out drives. Previous owner had the shortblocks rebuilt and a good valve job put on the heads, but didn't reassemble. Then he said he had both out drives "rebuilt" but I'll have to get further details on what was done there. I've replaced driveshaft u-joints, gimble bearings, and everything that goes around/seals the outdrive. It was work, but I got it done on my old Chris Craft so I'm sure I could do it on these if need be.

If anyone has any pictures of a Straight 6 cylinder mercruiser setup in an engine bay that can show me where the motor mounts go, that would be appreciated. I'm assuming from what I found that it has a single motor mount at the very front of the motor considering there are no mounts/holes on the sides of either engine. I haven't seen the engines yet, but am supposed to go pick them up this Friday if time permits. The guy lives in my neighborhood.

I started cleaning her out this week, maybe 30 minutes to an hour a day to pump the water out and clean out the leaves/trash that has accumulated over the years. I've got it to a point where I can either use my blower or vacuum cleaner to get the rest of the leaves/debris out and got a good cleaned up area to work with and get a few pictures.

I've been reading iBoats off and on for a few years now. I started reading when I figured out that my 97 Chris Craft 170 ski boat was going to need a transom. I decided that job was too tough for me to tackle at the time and took the boat to a local fiberglass shop to get it done and he did a great job. The boat is solid and doesn't get a drop of water in it unless the kids get in soaking/dripping wet LOL. That said I know I need to drill a few core samples of the transom and stringers. From what I've found online the 1978 Sea Ray was the last year that Sea Ray used the extra thick fiberglass method to build the boat. So it is considered to be pretty heavy duty in terms of construction. I'm really hoping the stringers are OK and honestly hope the transom is OK too because that's a big transom and a lot of work on top of having to potentially rewire, replace the steering, replace the engine cover floor door, replace the throttle assembly, replace all carpeting/padding below, and who knows what else. At this point, I just want a good dependable boat that I can take a couple miles off shore and go scuba dive some rigs in the gulf. The cosmetics can be done later as time/money permits. I just need the drivetrain to be solid first.

I haven't snapped any pics in the cabin area yet, but I'll get those and post them eventually. The few pics I have were mostly taken in the evening after I cleaned out a bunch of trash. I just wanted to get some shots of the engine bay and key holes up here so you guys could take a look and give me your thoughts.

The engines I'm told are straight 6 cylinders with Mercruiser out drives. Previous owner had the shortblocks rebuilt and a good valve job put on the heads, but didn't reassemble. Then he said he had both out drives "rebuilt" but I'll have to get further details on what was done there. I've replaced driveshaft u-joints, gimble bearings, and everything that goes around/seals the outdrive. It was work, but I got it done on my old Chris Craft so I'm sure I could do it on these if need be.

If anyone has any pictures of a Straight 6 cylinder mercruiser setup in an engine bay that can show me where the motor mounts go, that would be appreciated. I'm assuming from what I found that it has a single motor mount at the very front of the motor considering there are no mounts/holes on the sides of either engine. I haven't seen the engines yet, but am supposed to go pick them up this Friday if time permits. The guy lives in my neighborhood.

Last edited: