Mizedog

Cadet

- Joined

- Mar 8, 2016

- Messages

- 10

Good morning all,

I am starting this thread for three reasons:

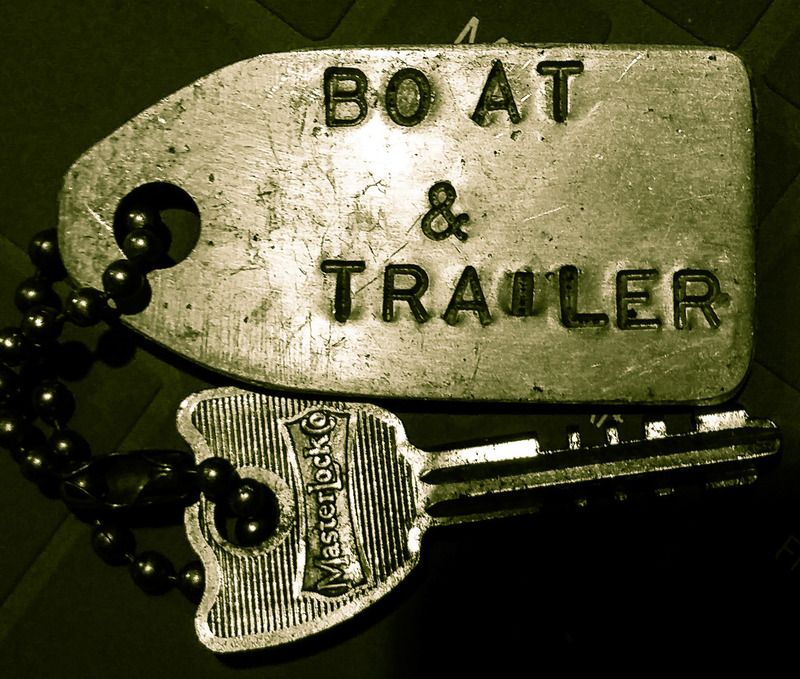

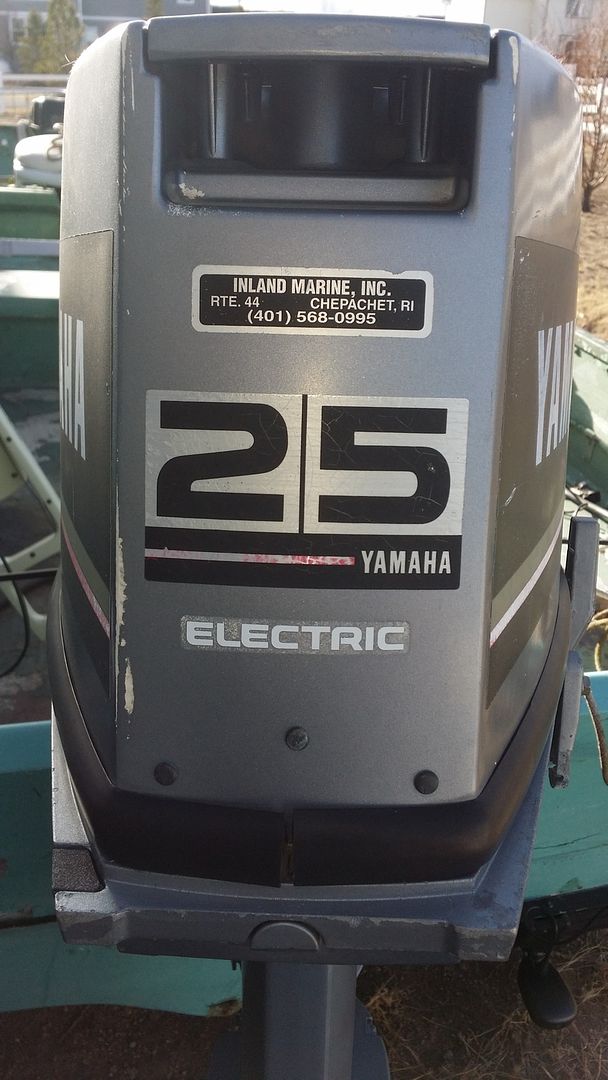

1. Document my thoughts, ideas, and plans to restore my dear Grandpa's (Edward Mitchell) boat

2. Humbly absorb suggestions and ideas from the wisdom of those here who know

3. Honor my Grandpa's planning, creativity and history of lake fishing

My Grandpa Mitchell bought this boat when I was just a year or so old and loved to remind me of that. I caught my first fish in the Kankakee River in Indiana from this boat using my first Zebco rod. Grandpa fished from this boat into his 90's, and the boat passed to my father, and now to me. I really want to fix it up so my two daughter's can learn the joy of fishing from me, and my father, and have a tangible thing to know their great grandfather by.

Thanks in advance for any help you all can provide. More to come!

I am starting this thread for three reasons:

1. Document my thoughts, ideas, and plans to restore my dear Grandpa's (Edward Mitchell) boat

2. Humbly absorb suggestions and ideas from the wisdom of those here who know

3. Honor my Grandpa's planning, creativity and history of lake fishing

My Grandpa Mitchell bought this boat when I was just a year or so old and loved to remind me of that. I caught my first fish in the Kankakee River in Indiana from this boat using my first Zebco rod. Grandpa fished from this boat into his 90's, and the boat passed to my father, and now to me. I really want to fix it up so my two daughter's can learn the joy of fishing from me, and my father, and have a tangible thing to know their great grandfather by.

Thanks in advance for any help you all can provide. More to come!