thebrain

Banned

- Joined

- Jun 3, 2010

- Messages

- 358

Inboard outboard conversion to OB an donor boat?s

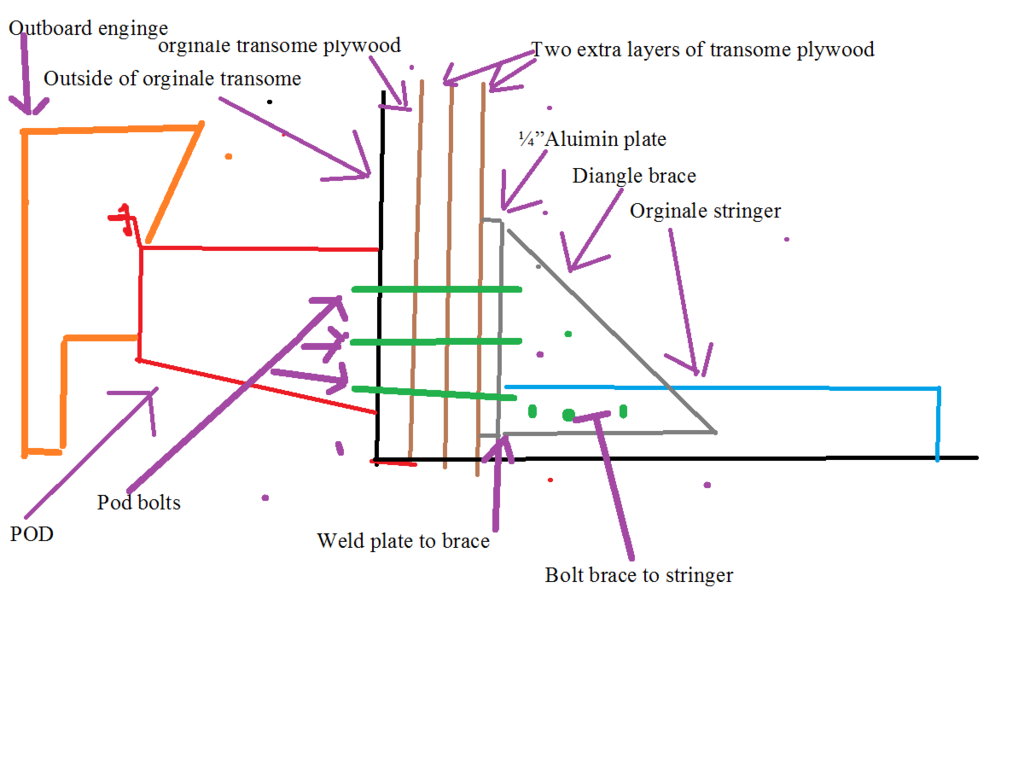

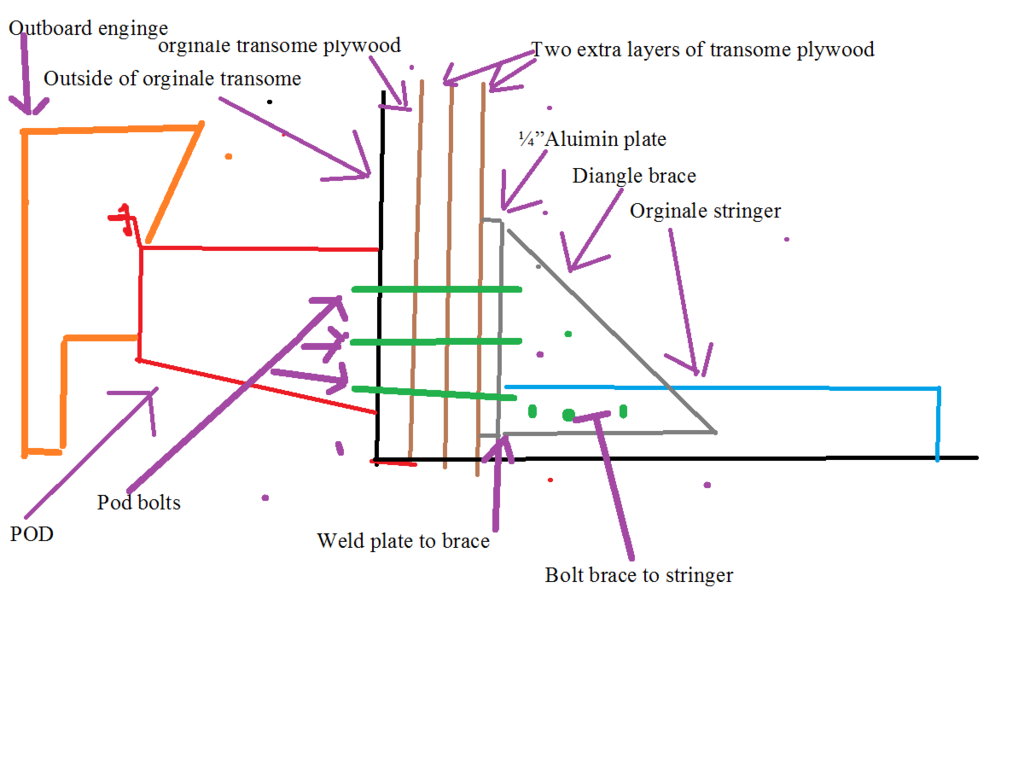

Im planning a Inboard outboard conversion to OB (minimum 150HP max 250HP) on a 1977 Starcraft Chieftain its a 22 aluimin cabin cruiser hull weight is 1650LBs using a Armstronge stainless steel transome bracket engine pod rated at 275HP simiairl to this swap attached image.

I believe the orginale SC transome (which is in good shape looking from the inside) only has one piece of ? Plywood.

Can I glue two more ? piece together making a 1 1/2' then screw it to the orginale plywood and expect it to be stronge enought?

Step two of my plan would have a ? square of a aluimin wider than the POD and same width as the stringers plan to weld angle braces to plate then bolt to stringer.

I was planning to trace out the stern drive hole and cut a piece of same thickness ? Ply as the orginale transome glue it in then cover w/ a aluimin street sign screwed to outside of transome

Step two here would be to smear JB cold weld around sign to make water tight seal.

Hows the easiest way to locate to POD on the transome Im thinking to attach pod to engine connect engine to cherry picker then have a straight edge on keel raise or lower Pod and engine until the cavatation plate is even w/ keel?

Attached images of a simiarl Starcaft of close to the same era white blue boat pod is even w/ keel.

Second newer black boat the pod is not even w/ keel.

I would prefer a XL shafted engine to keep the engine up out of water as much as possible will I have to use a 25 shafted engine ? like will a 20 be to short?

Any tips on this conversion is appreciated.

Donor boat

Will a bass boat (as a donor boat) controls/throttle cable and steering cable be to short to swap into the cabin cruiser? The helm on CC is located approximately halfway on hull.

The rear section of chieftain floor is removed to bach of helm station so instead of routeing controls to starboard side and mount to SB side I could reroute controls directly

To left side of helm station.

Any advice on this is appreciated

TB

Im planning a Inboard outboard conversion to OB (minimum 150HP max 250HP) on a 1977 Starcraft Chieftain its a 22 aluimin cabin cruiser hull weight is 1650LBs using a Armstronge stainless steel transome bracket engine pod rated at 275HP simiairl to this swap attached image.

I believe the orginale SC transome (which is in good shape looking from the inside) only has one piece of ? Plywood.

Can I glue two more ? piece together making a 1 1/2' then screw it to the orginale plywood and expect it to be stronge enought?

Step two of my plan would have a ? square of a aluimin wider than the POD and same width as the stringers plan to weld angle braces to plate then bolt to stringer.

I was planning to trace out the stern drive hole and cut a piece of same thickness ? Ply as the orginale transome glue it in then cover w/ a aluimin street sign screwed to outside of transome

Step two here would be to smear JB cold weld around sign to make water tight seal.

Hows the easiest way to locate to POD on the transome Im thinking to attach pod to engine connect engine to cherry picker then have a straight edge on keel raise or lower Pod and engine until the cavatation plate is even w/ keel?

Attached images of a simiarl Starcaft of close to the same era white blue boat pod is even w/ keel.

Second newer black boat the pod is not even w/ keel.

I would prefer a XL shafted engine to keep the engine up out of water as much as possible will I have to use a 25 shafted engine ? like will a 20 be to short?

Any tips on this conversion is appreciated.

Donor boat

Will a bass boat (as a donor boat) controls/throttle cable and steering cable be to short to swap into the cabin cruiser? The helm on CC is located approximately halfway on hull.

The rear section of chieftain floor is removed to bach of helm station so instead of routeing controls to starboard side and mount to SB side I could reroute controls directly

To left side of helm station.

Any advice on this is appreciated

TB

Attachments

-

transomeforpod.jpg29.3 KB · Views: 2

transomeforpod.jpg29.3 KB · Views: 2 -

armstronge pod1.jpg23.7 KB · Views: 2

armstronge pod1.jpg23.7 KB · Views: 2 -

Pod2.jpg30.4 KB · Views: 2

Pod2.jpg30.4 KB · Views: 2 -

pod3.jpg22.4 KB · Views: 2

pod3.jpg22.4 KB · Views: 2 -

islanderpod1.jpg97.7 KB · Views: 2

islanderpod1.jpg97.7 KB · Views: 2 -

islanderpod2.jpg63.3 KB · Views: 2

islanderpod2.jpg63.3 KB · Views: 2 -

islanderpod3.jpg109.3 KB · Views: 2

islanderpod3.jpg109.3 KB · Views: 2 -

newerislanderpod.jpg70.7 KB · Views: 2

newerislanderpod.jpg70.7 KB · Views: 2 -

PODbracedp.png36.2 KB · Views: 2

PODbracedp.png36.2 KB · Views: 2

Last edited: