Last year I purchased a project boat that I am planning to start restoration next month.

The project is not as challenging as other members are doing, but being my first aluminum boat and the lack of documentation about this particular boat, makes it difficult for me.

Based on the Serial Number, the boat is: 1981 Springbok, 18 foot, 81" beam. Some people called it Alcan Jumbo, but I am not sure if this is the same model.

Since I purchased the boat without any plate for specifications, my first question will be:

For now, this is what I think I need to do:

a. rebuild the transom (since the previous owner cut it for 15?, I built it for 15? for testing purpose with a small outboard and if it is a good fit for me, I will build a 20? transom and buy a bigger outboard.

b. fill up the flotation compartments (benches) with foam

c. cover the benches with plywood

d. build the diagonal stringers from gunnels to the benches (2 per bench)

e. build a small bow cap

f. build the bow ?platform? ? the triangular one that is flush with the gunnels (I don?t know the actual term for it)

g. install the bilge drain

h. install a bilge pump

Now, a bunch of questions:

2. Outboard: 40 HP 4 tiller. Too small?

3. Flotation: To allow water to flow towards the bilge pump and to avoid the foam soaking water, I am thinking to add a layer of 0.5Liter PET bottles on the bottom, then Styrofoam blocks on top. Based on my calculations, the bottles are 4lb/ft3 and the foam is 2lb/ft3, so there is a difference, but if it is only the bottom layer, it is not that bad. Good idea or bad idea?

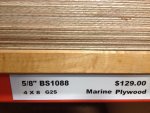

4. Plywood for benches: I will use Baltic Birch, covered in 3 layers of East Systems epoxy. The question is what thickness for the plywood? It takes an effort to snuggly fit ? and I am wondering if I should go one size thinner, 5/8?

5. Diagonal Stringers: I saw on other boats these stringers are not just flat metal, but they have some shape along that makes them a lot harder to bend. Any idea how to achieve that, or will it be OK to use flat strips?

6. The bow ?platform?: In the fourth picture below, there is a boat exactly like mine (I think they are actually the same model). The bow platform seems to be arched, but I am planning to add a trolling motor at the bow, so if I can get away with just a big piece of plywood on top of the gunnels and riveted to the gunnels, that would be the best for me. In my opinion, I am not losing any strength? How thick should be the plywood?

The bilge drain: It came with a schematic, but it is not clear for me if I install it with the already flanged side inside the boat or outside? Also, the rubber O-ring should be inside the boat or outside? Should I add some 3M 5200 when I install it? Some people mentioned they put adhesive, but since the one I have has an O-ring, do I still need adhesive?Anything else you think needs to be done?

Thanks a lot for taking the time to read my post. Any advice is highly appreciated.

The project is not as challenging as other members are doing, but being my first aluminum boat and the lack of documentation about this particular boat, makes it difficult for me.

Based on the Serial Number, the boat is: 1981 Springbok, 18 foot, 81" beam. Some people called it Alcan Jumbo, but I am not sure if this is the same model.

Since I purchased the boat without any plate for specifications, my first question will be:

- if any of you have any knowledge about the specs, please let me know. If you see one for sale, please let me know so I can get in touch with the owner and ask for specs.

For now, this is what I think I need to do:

a. rebuild the transom (since the previous owner cut it for 15?, I built it for 15? for testing purpose with a small outboard and if it is a good fit for me, I will build a 20? transom and buy a bigger outboard.

b. fill up the flotation compartments (benches) with foam

c. cover the benches with plywood

d. build the diagonal stringers from gunnels to the benches (2 per bench)

e. build a small bow cap

f. build the bow ?platform? ? the triangular one that is flush with the gunnels (I don?t know the actual term for it)

g. install the bilge drain

h. install a bilge pump

Now, a bunch of questions:

2. Outboard: 40 HP 4 tiller. Too small?

3. Flotation: To allow water to flow towards the bilge pump and to avoid the foam soaking water, I am thinking to add a layer of 0.5Liter PET bottles on the bottom, then Styrofoam blocks on top. Based on my calculations, the bottles are 4lb/ft3 and the foam is 2lb/ft3, so there is a difference, but if it is only the bottom layer, it is not that bad. Good idea or bad idea?

4. Plywood for benches: I will use Baltic Birch, covered in 3 layers of East Systems epoxy. The question is what thickness for the plywood? It takes an effort to snuggly fit ? and I am wondering if I should go one size thinner, 5/8?

5. Diagonal Stringers: I saw on other boats these stringers are not just flat metal, but they have some shape along that makes them a lot harder to bend. Any idea how to achieve that, or will it be OK to use flat strips?

6. The bow ?platform?: In the fourth picture below, there is a boat exactly like mine (I think they are actually the same model). The bow platform seems to be arched, but I am planning to add a trolling motor at the bow, so if I can get away with just a big piece of plywood on top of the gunnels and riveted to the gunnels, that would be the best for me. In my opinion, I am not losing any strength? How thick should be the plywood?

The bilge drain: It came with a schematic, but it is not clear for me if I install it with the already flanged side inside the boat or outside? Also, the rubber O-ring should be inside the boat or outside? Should I add some 3M 5200 when I install it? Some people mentioned they put adhesive, but since the one I have has an O-ring, do I still need adhesive?Anything else you think needs to be done?

Thanks a lot for taking the time to read my post. Any advice is highly appreciated.

Attachments

Last edited: