I am about to purchase the epoxy and mat this weekend. I was wondering how much would be enough. I am just building a casting deck- I have 3/4th marine grade wood in a 48x24in sheet, will be cut to about 40x24in. I plan to coat it with epoxy then a single layer of fiberglass. Approximately how much resin/hardener would I need? I was probably going to purchase from us composites in the 4 to 1 Fast hardener since I am here in Ft Lauderdale the temp is rarely below 80F. I was also planning on patching together a small floor addon for a CC- but that can come later.

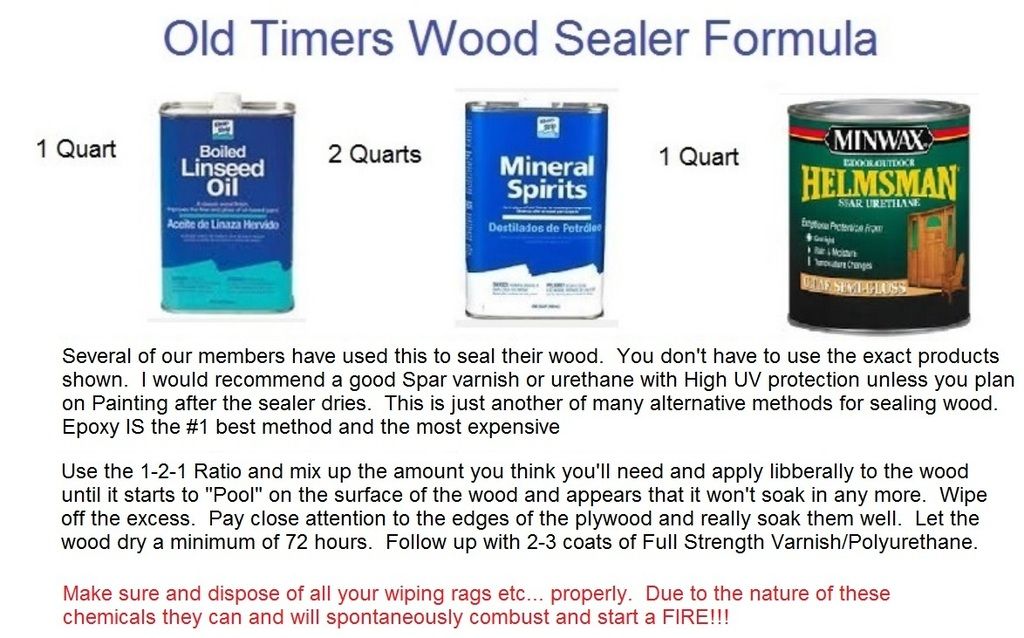

So a few questions- is this the direction you would go? The standing platform is not going to be permanently mounted on the boat, so should I consider other methods? Perhaps a penetrating solution and a paint sealant instead? Is the 4 to 1 Fast a good idea? Any cheaper alternatives in terms of sourcing the epoxies? Any help is really appreciated. I can supply pics of my project if needed to get a better understanding.

Thanks

So a few questions- is this the direction you would go? The standing platform is not going to be permanently mounted on the boat, so should I consider other methods? Perhaps a penetrating solution and a paint sealant instead? Is the 4 to 1 Fast a good idea? Any cheaper alternatives in terms of sourcing the epoxies? Any help is really appreciated. I can supply pics of my project if needed to get a better understanding.

Thanks