lol time to break out the chainsaw...

Yea, I know . . . seriously

However, my chainsaw is on the fritz right now, so I'll just have to deal with the boat as is.

After giving my predicament some thought, I came up with a plan to separate the boat halves without any serious cutting. I do know that serious is a relative term though.

Anyway, I have sketched out a way that I think will work, be minimally invasive and easy to 'fix' when it is time to put the boat back together.

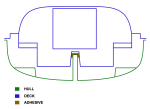

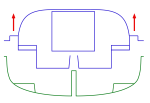

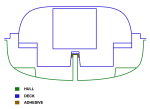

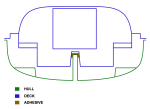

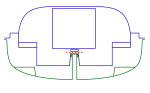

Here is a cross-section of my boat in the area of the cockpit and keel trunk. The green is the hull assembly, the purple is the deck/cockpit assembly, and the brown is the culprit adhesive that is holding the two boat halves together.

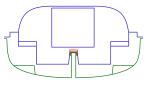

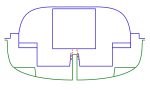

The top of the keel trunk within the cockpit has a 1/2" plywood core for hardware mounting, etc. Shown by the red rectangle in the pic below . . .

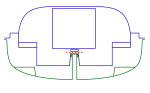

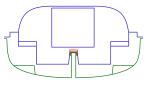

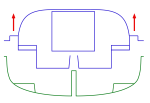

My plan is to cut the cockpit keel trunk just below the core material . . . This will open up the hidden adhesive area as well as the keel trunk itself.

I can then make downward cuts along the exposed keel trunk to separate remaining adhesive holding the two pieces of boat together.

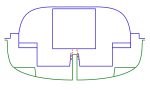

This will hopefully result in the boat halves breaking free and I can lift the deck assembly up off of the hull.

On the return trip, I would replace the top piece that I cut away from the cockpit prior to re-assembly, and join the boat halves much in the same way the factory builds new Mariners.

So, that is the plan at this point. I probably will have some time next weekend to make the cuts. If it all goes well, I'll have to figure out how to get both boat 'pieces' in the garage for the winter, so I can continue the restoration work.