viktormizer

Recruit

- Joined

- Apr 12, 2011

- Messages

- 4

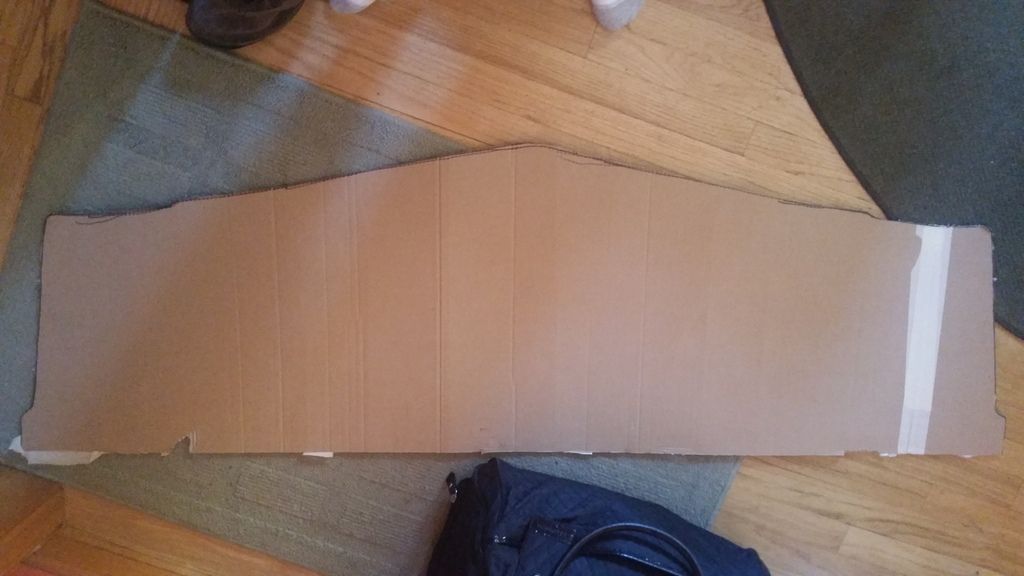

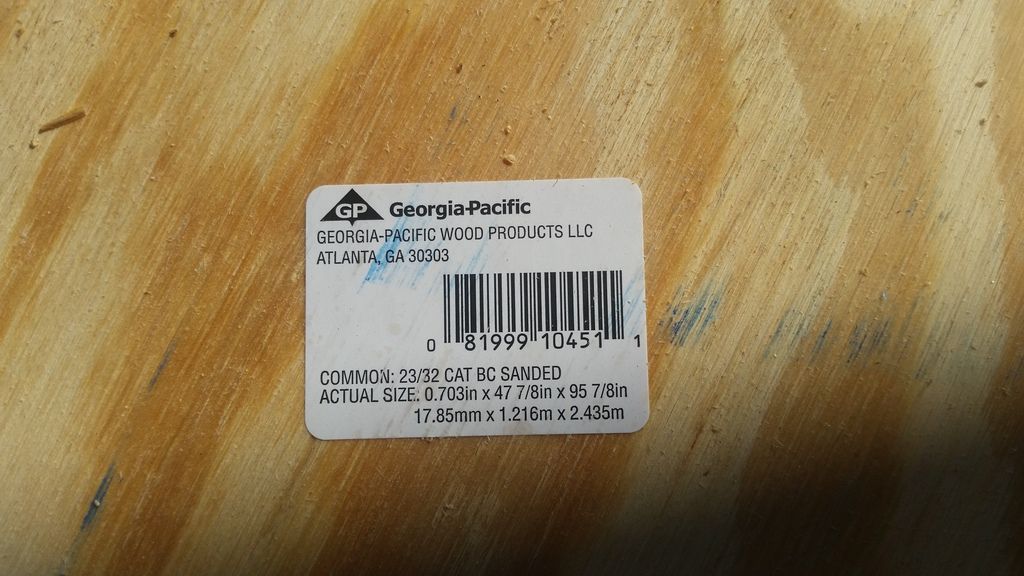

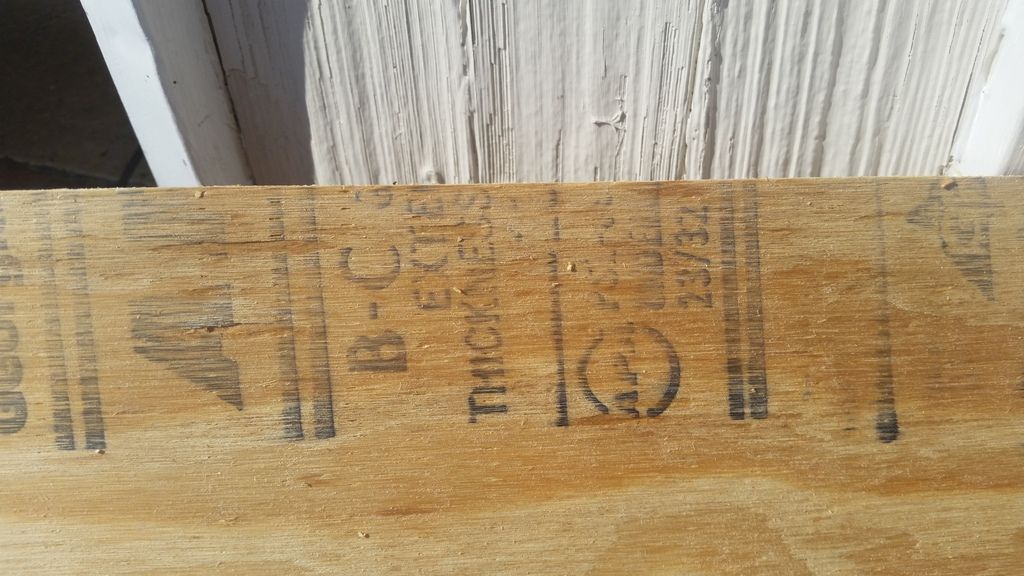

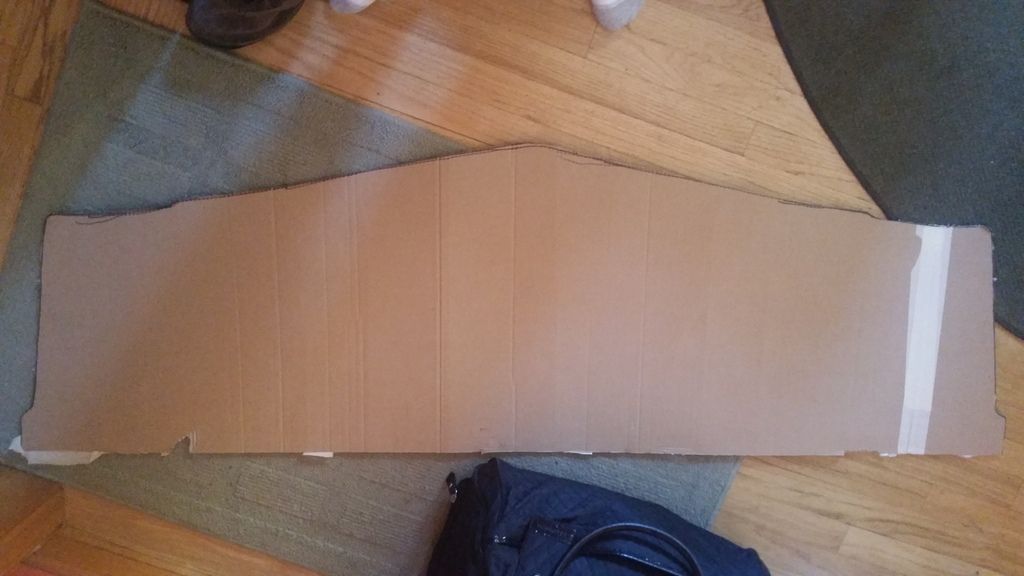

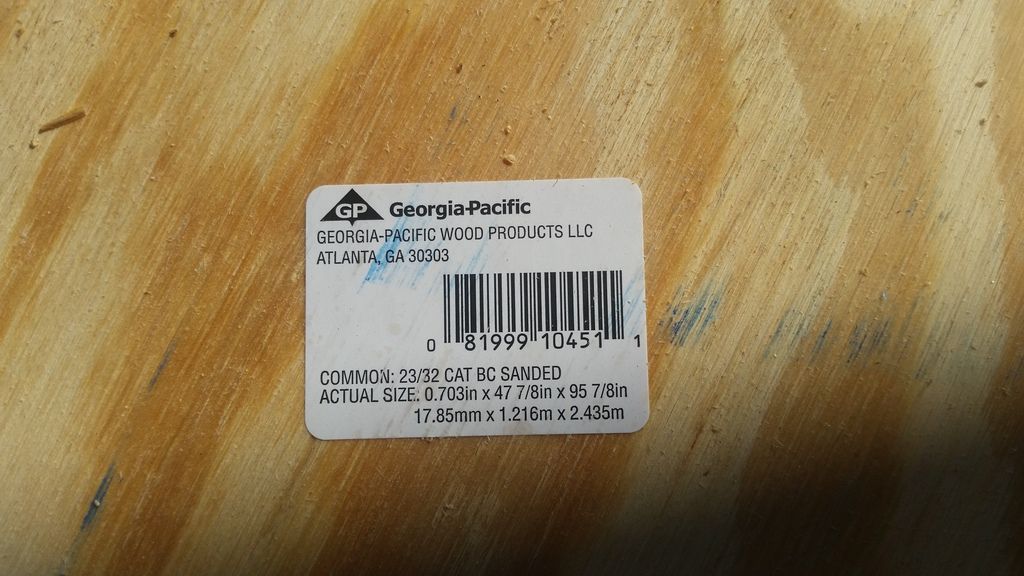

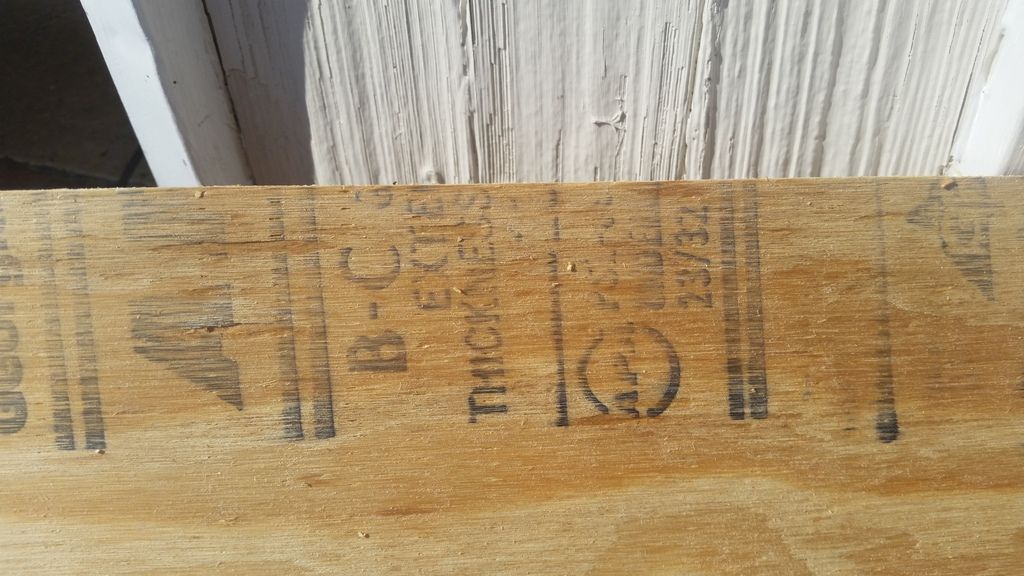

Picked up pretty cheap with trailer and paper work this 1972 Westwind trihull powered by a 1967 60 hp Johnson Super Sea Horse VXL -13a with good compression. Got out for a season without a problem but once I started getting in there I realize that it was a pretty bad idea to be anywhere near the water without fixing her proper. The stringers were gone there was just some floating stringers not contacting the hull and not glassed in, just screwed into the remaining part of the old deck to sit the replacement ply on. Transom is mush with a metal bar across. Long story short I have the cap pulled and hull semi gutted. I also made a template cut two 4x8 3/4" BC sanded exterior Plywood from lowes (Plytanium) to size and laminated with titebond 3 wood glue. That's where i'm at as of today.I figure if I make it official by putting up a thread I will be a little less inclined to BS and actually get this thing back on the water, not to mention the help that i see is available by lurking this forum since 2011. Im not looking to turn heads, just a basic rebuild that I know is safe and can get me out fishing again ( but def a paint job). Going all poly using woodonglass's layup schedule as a guide. Ill try to post Some good pics so anyone interested and willing to drop a little knowledge can follow along . Thanks in advance.

Last edited: