bonz_d

Vice Admiral

- Joined

- Apr 22, 2008

- Messages

- 5,276

The 1984 Sea Nymph FM144 I recently purchased came with a Mini-Jack jack plate. The boat has a short transom with the jack plate added for a long shaft. Also this boat must have had a Merc on it because those are the controls that were in it.

I have installed a 1994 30hp Johnson long shaft on it and am getting horrible performance. Boat takes forever to come up out of the hole and while it is the bow is very high. Below 1/2 throttle the stern drops again and the bow comes up. When running at 3/4 or better throttle it is producing a very high spray from the lower unit. I believe the engine is still too low and causing the problem.

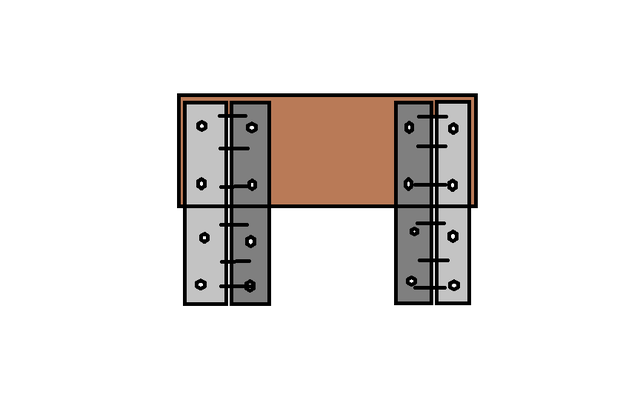

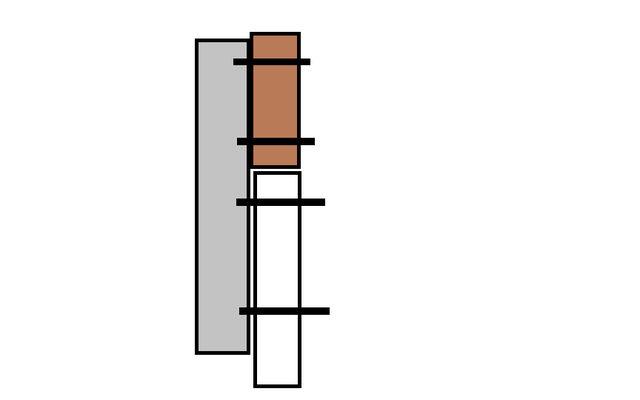

Thing is that I have never worked with a jack plate before and have no clue. This plate has a 4" setback. Mounted with 4 bolts thru the transom and while I 1st thought there were other holes to move it up or down there are not. So I don't want to just start drilling more holes in either the plate or the transom before I get an idea as to how to adjust this.

Thanks, here are a few pictures for reference.

I have installed a 1994 30hp Johnson long shaft on it and am getting horrible performance. Boat takes forever to come up out of the hole and while it is the bow is very high. Below 1/2 throttle the stern drops again and the bow comes up. When running at 3/4 or better throttle it is producing a very high spray from the lower unit. I believe the engine is still too low and causing the problem.

Thing is that I have never worked with a jack plate before and have no clue. This plate has a 4" setback. Mounted with 4 bolts thru the transom and while I 1st thought there were other holes to move it up or down there are not. So I don't want to just start drilling more holes in either the plate or the transom before I get an idea as to how to adjust this.

Thanks, here are a few pictures for reference.